The Air Force Research Laboratory in collaboration with research partners at Los Alamos National Laboratory has devised a 3-D printed polymer-based foam structure that responds to the force of a shock wave to act as a one-way switch, a long-sought-after goal in shock research. This new technology could potentially be scaled up in order to be used in different ways for a variety of applications, including for the protection of structures.

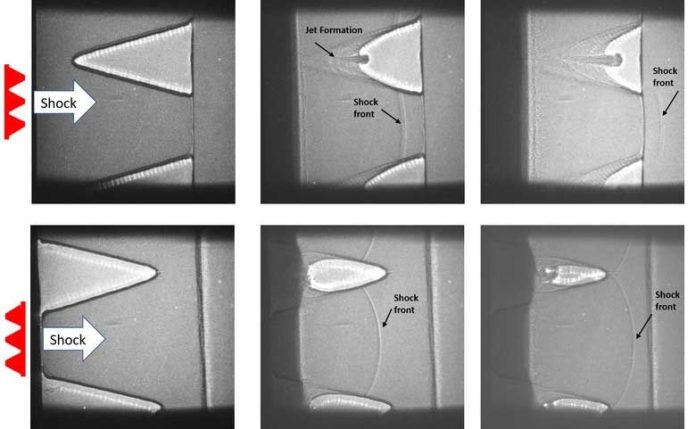

In reality, this 3-D printed polymer-based foam structure contains a series of specifically-engineered tiny holes that determine the overall behavioral characteristics. When these cones encounter a shock wave, they collapse inward, forming jet protrusions that project from the opposite side. These jets localize the shock wave energy, which is the origin of the material’s unique directional behavior.

Scientists used computer modeling trials for over a month to determine the most effective hole geometries to achieve the desired material response.

AFRL Senior Materials Research Engineer Dr. Jonathan Spowart said, “The team would print a small test article, a flat plate not much bigger than a pencil eraser. With the help of Los Alamos National Laboratory, working on-site at the Dynamic Compression Sector user facility at Argonne National Laboratory, they would then conduct tests and image the specimen using X-rays to determine performance.”

Spowart said, “When we would arrive at a promising configuration, we would print a small test article, a flat plate not much bigger than a pencil eraser. With the help of Los Alamos National Laboratory, working on-site at the Dynamic Compression Sector user facility at Argonne National Laboratory, they would then conduct tests and image the specimen using X-rays to determine performance.”

For additional modeling, scientists would review the outcomes and fine-tune the material if required.

Spowart said, “This effort represents a significant breakthrough in materials engineering. He attributes this success to the collaboration, communication, and expertise of the teams at AFRL, Los Alamos, and Argonne National Laboratory, as well as the basic research funding from AFOSR.”

“The materials technology came from AFRL crediting the modeling and materials expertise of the project team. The testing facilities and test methodology came from Los Alamos. So when you put the two things together, you get a really good team.”

“The remarkable test imaging provided by Argonne National Laboratory was crucial in proving out the concept. The laboratory’s Advanced Photon Source synchrotron is a unique piece of equipment that fires a very powerful and concentrated X-ray beam at the test article, allowing frame-by-frame imaging of a shock wave penetrating the specimen, all of which occurs within a few nanoseconds.”

“This new imaging capability, together with the new manufacturing technology and computer simulations, allowed the team to obtain images and evaluate concepts in ways that were well beyond reach just a few years ago.”

Los Alamos National Laboratory scientist Brittany Branch, who led the dynamic experiments said, “The Dynamic Compression Sector is a unique facility that enables in-situ imaging of dynamic events giving us unprecedented information of the microstructural effects on dynamic behavior. Traditional shock compression diagnostics would not elucidate the localization phenomena that is occurring during shock compression. We would see a difference in shock velocity with traditional techniques, but not understand why. These experiments were very exciting since we demonstrated a shock diode for the first time.”

Spowart said, “The team plans to publish their findings and work toward transitioning the technology for further maturation and integration into existing systems, where he believes this technology has tremendous potential. We are very excited about this effort and the teamwork that made it possible. This is a great example of what basic research can do to strengthen our capabilities.”