By using a technique called ‘in-air microfluidics’, scientists at the University of Twente succeed in developing 3D printed living cells. This extraordinary method empowers the quick and ‘on-the-fly’ creation of smaller scale building obstructs that are practical and can be utilized for repairing harmed tissue, for instance. The work is exhibited in ‘Science Advances‘.

Microfluidics is tied in with controlling minor drops of liquid with sizes between a micrometer and a millimeter. Regularly, chips with minor fluidic channels, reactors, and different parts are utilized for this: lab-on-a-chip frameworks.

In spite of the fact that these chips offer a wide scope of potential outcomes, in creating emulsions for instance – beads conveying another substance – the speed at which beads leave the chip is commonly in the microliter every moment extend. For clinical and modern applications, this isn’t sufficiently quick: filling a volume of a cubic centimeter would take around 1000 minutes or 17 hours. The system that is introduced now, does this in a few minutes.

Affecting JETS:

Would we be able to achieve these higher speeds by not controlling the liquids in miniaturized scale channels, but rather in the air? This was one of the inquiries the specialists needed to reply. What’s more, without a doubt it was conceivable, by utilizing two ‘planes’ of liquid. From one fly, beads are shot at the other fly.

Making the planes is generally straightforward, and they move 100 to 1000 times quicker than beads from a microchip. Speed isn’t the main preferred standpoint. By picking planes containing diverse kinds of liquids that respond, the ‘impact’ brings about new materials. Brilliant blends of liquids will bring about strong and printable building hinders in one single step.

Sponge:

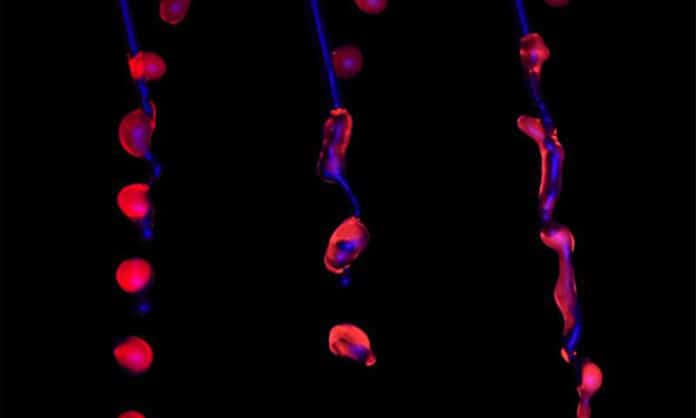

Along these lines, it is conceivable to catch a living cell inside a printable material. The subsequent bio building pieces are imprinted in a 3D structure that resembles a wipe, loaded with cells and liquid. These 3D particular biomaterials have an inner structure that is very like that of characteristic tissue. Numerous 3D printing strategies depend on utilizing warmth or UV light: both would harm living cells. The new microfluidic approach is in this manner a promising procedure in tissue engineering, in which damaged tissue is repaired by using cultured cell material of the patient.

The examination has been finished by Tom Kamperman of the Developmental BioEngineering gathering of Prof Marcel Karperien, and by Claas Willem Visser of the Physics of Fluids gathering of Prof Detlef Lohse. Kamperman just as of late completed his Ph.D. regarding this matter, Claas Willem Visser incidentally acts as a researcher at Harvard University on a Rubicon concede. He will come back to the University of Twente a short time later and turn into a partner educator. The two researchers are engaged with the new IamFluidics spinoff, in which in-air microfluidics is utilized to make practical particles and materials.