Synthesizing organic scaffolds that contain metal ions enables 3-D printing of metallic structures that are orders of magnitude smaller than previously possible. A team of scientists from Caltech Resnick Sustainability Institute invented a novel method to frame complex nanoscale metal structures utilizing 3-D printing.

The method, once scaled up, could be utilized in various utilities, from building modest medical implants to framing 3-D logic circuits on PC chips to engineering ultralightweight aircraft parts. It is likewise accessible to create a novel class of materials with unusual properties based on their internal structure.

In this kind of 3-D printing, also known as additive manufacturing, an object is framed layer by layer, permitting the creation of structures that would be tedious to manufacture by conventional subtractive techniques such as etching or milling.

Caltech materials scientist Julia Greer is a pioneer in the creation of ultrathin 3-D architectures framed via additive manufacturing.

For example, along with her team, they have built 3-D lattices whose beams are mere nanometers athwart, far too small to be seen with the naked eye. These materials demonstrate unusual, often astounding properties.

A group of scientists has framed particularly lightweight ceramics that spring back to their actual shape, like a sponge, after being restrained.

Greer’s group 3-D prints structures from various materials, from ceramics to organic amalgamations. Metals, however, have been tedious to print, especially when demanding to frame structures with magnitudes smaller than around 50 microns, or about half the width of a human hair.

In this recently invented method, two-photon lithography is utilized to 3-D print structures out of a liquid material, framing chemical bonds that harden into a solid material.

3-D printing works at the nanoscale because a high-precision laser zaps the liquid in particular locations of the material with mere two photons or particles of light. This procures sufficient energy to harden liquid polymers into solids but not sufficient to fuse metal

Greer, professor of materials science, mechanics, and medical engineering in Caltech’s Division of Engineering and Applied Science, said, “Metals don’t respond to light in the same way as the polymer resins that we use to manufacture structures at the nanoscale.”

“There’s a chemical reaction that gets triggered when light interacts with a polymer, enabling it to harden and then form into a particular shape. In a metal, this process is fundamentally impossible.”

Along with this, computer modeling demonstrates how modest lattice is 3-D printed in 150-nanometer layers. When the frame is heated, it can shrink by 80 percent.

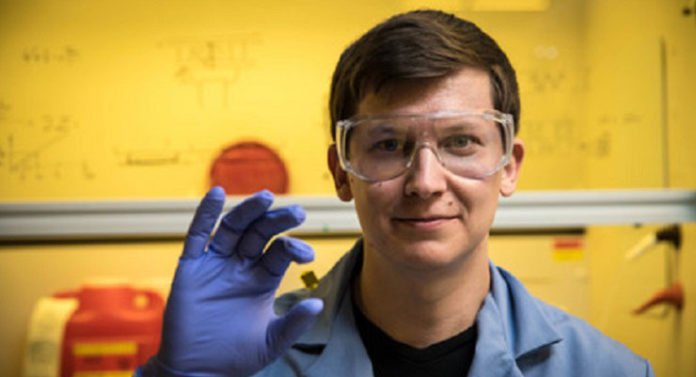

Greer’s graduate student, Andrey Vyatskikh, unveiled a key. He utilized organic ligands, molecules that bind to metal, to frame a resin accommodating mostly polymer, which carries metal that can be printed, like a scaffold.

In the investigation characterized in the Nature Communications paper, Vyatskikh bonded joined nickel and organic molecules to frame a liquid that looks a lot like cough syrup. They framed a structure utilizing PC software and then constructed it by zapping the liquid with a two-photon laser.

The laser built sturdy chemical bonds between the organic molecules, hardening them into building blocks for the structure. Since those molecules are likewise bonded to the nickel atoms, the nickel becomes incorporated into the structure.

This way, the team could print a 3-D structure that was initially a blend of metal ions and nonmetal organic molecules. Greer crushes the resulting structure and records its reaction to test its strength.

After this, Vyatskikh put the structure into an oven that gradually heated it up to 1,000 degrees Celsius (around 1,800 degrees Fahrenheit) in a vacuum chamber. That temperature is well below the melting point of nickel (1,455 degrees Celsius, or about 2,650 degrees Fahrenheit). Still, it is sufficiently hot to vaporize the organic materials in the structure, leaving only the metal. The heating process, known as pyrolysis, also fused the metal particles.

In addition to this, since the process vaporized a significant amount of the structure’s material, its magnitudes shrank by 80 percent, but it managed its shape and proportions.

Vyatskikh, lead author on the Nature Communications paper, stated, “That final shrinkage is a big part of why we’re able to get structures to be so small.”

“In the structure we built for the paper, the diameter of the metal beams in the printed part is roughly 1/1000th the size of the tip of a sewing needle.”

Greer and Vyatskikh are still refining their technique. Currently, the structure reported on in their paper comprised some voids left behind by the vaporized organic materials and some minor impurities.

Also, Greer says, if the technique is to be useful for industry, it will require being scaled up to produce much more material.

Although they started with nickel, they are attentive in expanding to other metals normally utilized in the industry but are challenging or tedious to fabricate in small 3-D shapes, such as tungsten and titanium.

Greer and Vyatskikh are likewise looking to utilize this technique to 3-D print other common and exotic materials, such as ceramics, semiconductors, and piezoelectric materials (materials with electrical effects that result from mechanical stresses).

Co-authors include Caltech Resnick Sustainability Institute Postdoctoral Scholar in Applied Physics and Materials Science Akira Kudo and mechanical engineering graduate student Carlos Portela as well as collaborators Stéphane Delalande of the Centre Technique de Vélizy in France and Xuan Zhang of Tsinghua University in China.

Journal Reference:

- Vyatskikh, A., Delalande, S., Kudo, A. et al. Additive manufacturing of 3D nano-architected metals. Nat Commun 9, 593 (2018). DOI: 10.1038/s41467-018-03071-9