People with prosthetic limbs live in a world without touch. In order to restore some semblance of this sensation, Stanford scientists have created stretchable, electronically sensitive synthetic materials. According to them, this leap forward would one be able to day fill in as skin-like covers for prosthetics.

They also suggest that the technology is also the foundation of a new genre of flexible electronics that are in stark contrast with rigid smartphones.

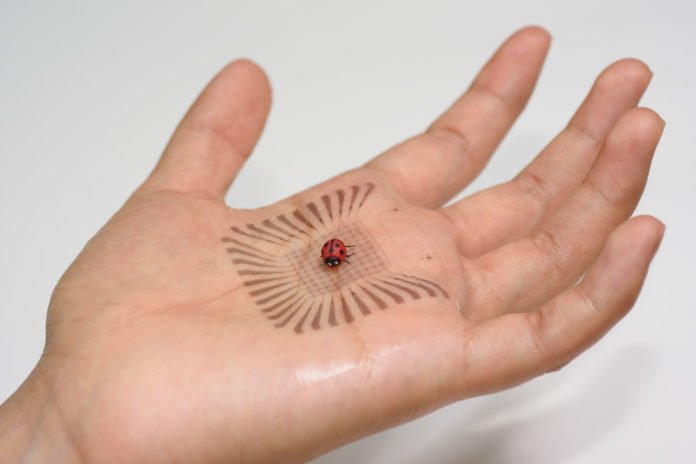

In a Feb. 19 polymer circuitry with integrated touch-sensors to detect the delicate footprint of an artificial ladybug. while this specialized accomplishment is a breakthrough, the second, and more common sense, progress is a strategy to mass deliver this new class of adaptable, stretchable gadgets – a basic advance on the way to commercialization.

Stanford chemical engineer Zhenan Bao said, “Research into the synthetic skin and flexible electronics has come a long way, but until now no one had demonstrated a process to reliably manufacture stretchable circuits.”

According to him, manufacturers might one day be able to make sheets of polymer-based electronics embedded with a broad variety of sensors, and eventually connect these flexible, multipurpose circuits with a person’s nervous system. Such a product would be analogous to the vastly more complex biochemical sensory network and surface protection “material” that we call human skin, which can not only sense touch but temperature and other phenomena, as well.

He said, “We’ve engineered all of these layers and their active elements to work together flawlessly.”

The production process involves a few layers of new-age polymers, some that furnish the material’s versatility and others with unpredictably designed electronic cross sections. In any case, others fill in as protectors to confine the electronically touchy material. One stage in the creation procedure includes the utilization of an inkjet printer to, fundamentally, paint on specific layers.

Scientists fashioned the material in a two-inch square that has almost 6,000 individual signal-processing devices. All this is encapsulated in a waterproof protective layer. Moreover, the material can be stretched to double its original dimensions – and back again while maintaining the electrical conduction.

During experiments, scientists stretched a sample more than one thousand times without significant damage or loss of sensitivity. The real test came when the researchers adhered their sample to a human hand.

Postdoctoral scholar Jie Xu said, “It works great, even on irregularly shaped surfaces.”