Magnetic fields in an electric drive are created in order to transform electric energy into kinetic energy. Likewise, electrical steel sheets also possess the decisive factor in the efficiency of the electric motor.

The way these steel sheets processed is actually Technical University of Munich (TUM). Scientists even have inferred that utilizing obtuse cutting devices disintegrates the attractive properties of the steel sheets altogether.

Untersuchung an Elektroblechen – Starke magnetfelder durch schafe Kanten

Foto: Andreas Heddergott / Verwendung frei fuer die Berichterstattung ueber die TU Muenchen unter Nennung des Copyrights

Current feedback of electro-versatility, for the most part, centers around long battery charging times and lacking reach. Analysts are attempting to expand the effectiveness of electric drives with a specific end goal to lessen the vitality necessities of electric vehicles.

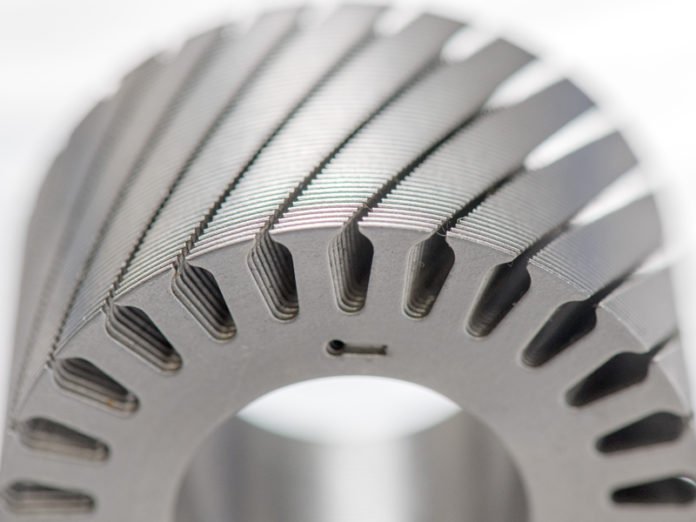

This includes an extensive number of individual segments, specifically electrical steel sheets: These sheets are imperative since the attractive fields that move the engine utilizing appealing and unpleasant powers are created inside them.

Contingent upon the engine’s plan, a wide range of gaps must be cut in the steel sheets, for instance, to prepare for copper loops incorporated with the engine. Each steel sheet is “stamped” exclusively in a press, utilizing an indistinguishable guideline from an opening punch.

Untersuchung an Elektroblechen – Starke magnetfelder durch schafe Kanten

Foto: Andreas Heddergott / Verwendung frei fuer die Berichterstattung ueber die TU Muenchen unter Nennung des Copyrights

Exceptional slicing apparatuses are utilized to guarantee that the predetermined geometries are made in the steel sheets. At last, the steel sheets are assembled with a specific end goal to frame the coveted shape.

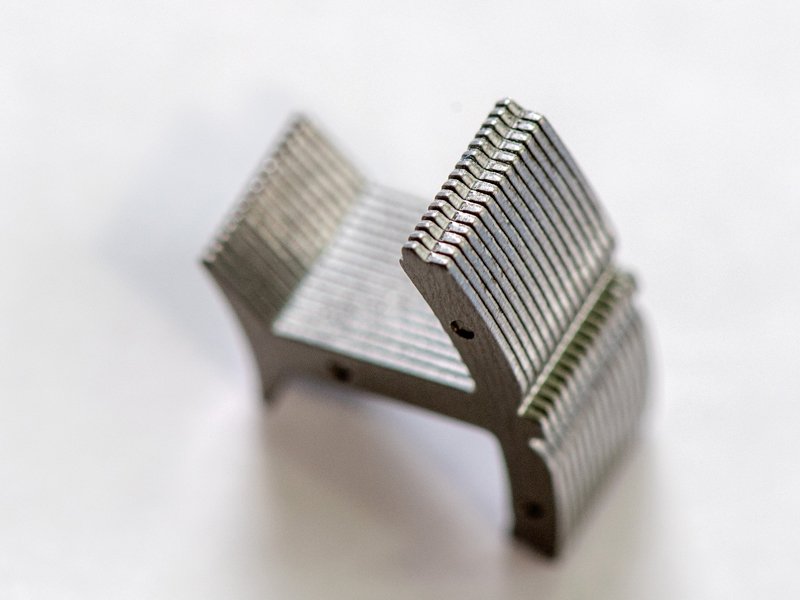

Amid the scientists demonstrating the process, they found that the sharpness of the cutting apparatuses utilized has an extremely noteworthy effect on the attractive properties of the steel sheets. The impact can be contrasted with a couple of scissors which dulls after some time: More vitality is expected to cut paper with the scissors.

Project director Hannes Weiss said, “We wanted to examine how manufacturing the electrical steel sheets by blanking influences their magnetic properties. Regarding blanking, worn cutting edges result in higher tension in the steel sheets themselves – the material is bent and thus subject to increased mechanical stress. The resulting stress has a major impact on magnetic properties. In some cases, as much as four times the amount of electricity is needed to achieve the same degree of magnetization.”

Untersuchung an Elektroblechen – Starke magnetfelder durch schafe Kanten

Foto: Andreas Heddergott / Verwendung frei fuer die Berichterstattung ueber die TU Muenchen unter Nennung des Copyrights

Another factor additionally has a noteworthy impact, the separation between the bleeding edges, alluded to as the cutting leeway. By and by, the procedure can be delineated utilizing the case of scissors: When the screw which holds the scissor cutting edges together extricates, the separation between the sharp edges turns out to be too extensive and the paper conflicts when cut. Sharp bleeding edges and a little cutting leeway are ideal for accomplishing the best attractive properties and consequently an abnormal state of proficiency.

Moreover, scientists explained, “economic factors also have to be taken into account. When the cutting tools and their maintenance incur additional costs, the final price of the electric drives produced rises as well.”

Weiss said, “Processing electrical steel sheets are not only an important issue in the context of electric motors. The sheets are also used in transformers, for example in mobile phone chargers and computer power supplies. The researchers also want to focus on the processing methods in this context as well. If we think of the enormous number of transformers in use, then even a small increase in efficiency can save a large amount of energy.”

PUBLICATIONS:

Weiss, H. A. et al.: Loss reduction due to blanking parameter optimization for different non-grain oriented electrical steel grades. Electric Machines and Drives Conference (IEMDC), 2017 IEEE International, 2017; DOI: 10.1109/IEMDC.2017.8002188

Weiss, H. A. et al.: Influence of shear cutting parameters on the electromagnetic properties of non-oriented electrical steel sheets. Journal of Magnetism and Magnetic Materials Volume 421, 2016, 250-259; DOI: 10.1016/j.jmmm.2016.08.002