One of the main reasons orthopedic implants fail and become clinically problematic is bacterial colonization of load-bearing metallic implants. Antibiotics applied topically or systemically might not provide the best defense against colonization, mainly if a subsequent infection necessitates the surgical removal of implants and, in extreme circumstances, limbs.

In about 7% of implant surgery cases, doctors have to perform revision surgery, remove the implant, clean the area, add antibiotics, and put in another implant.

Solution:

Scientists at Washington State University have developed a novel surgical implant that can kill bacterial infections. During experiments, it could kill 87% of the bacteria that cause staph infections and remain strong and compatible with surrounding tissue.

The infection-fighting implant:

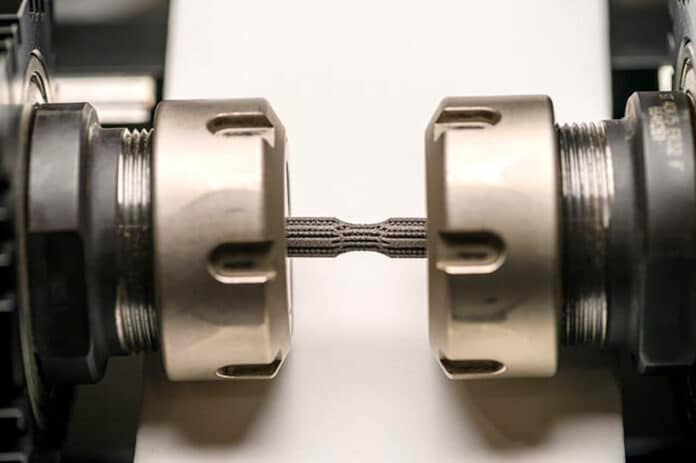

Scientists used 3D-printing technology to add 10% tantalum, a corrosion-resistant metal, and 3% copper to the titanium alloy.

Nearly all bacterial cell walls burst when they come into contact with the copper surface of the substance. Tantalum, in the meantime, promotes the formation of healthy cells in the surrounding bone and tissue, facilitating the patient’s healing process.

Scientists studied the implant’s mechanical properties, antibacterial response, and biological impact in labs and animal models for three years. They also examined how it wears to ensure that any metal ions from the implant don’t wear off and contaminate surrounding tissue.

Advantage:

Co-author Susmita Bose, Westinghouse Distinguished Professor in the school, said, “The biggest advantage for this type of multifunctional device is that one can use it for infection control and good bone tissue integration. Because infection is such a big issue in today’s surgical world, if any multifunctional device can do both things, there’s nothing like it.”

Future aspect:

This research may eventually result in improved infection management in numerous common surgeries carried out regularly worldwide, including knee and hip replacements.

Without compromising tissue integration, scientists hope to improve the bacterial death rate to a standard of greater than 99%. Additionally, they want to ensure that the materials operate well in loading scenarios that patients may encounter, such as hiking after a knee replacement.

Journal Reference:

- Amit Bandyopadhyay, Indranath Mitra, Sushant Ciliveri, Jose D Avila, William Dernell, Stuart B Goodman and Susmita Bose. Additively manufactured Ti–Ta–Cu alloys for the next-generation load-bearing implants. International Journal of Extreme Manufacturing. DOI: 10.1088/2631-7990/ad07e7