In material science, the physical factors that cause wrinkling remains a mystery.

Historically, scientists and engineers have focused on preventing wrinkling, which can adversely affect the performance of pressure sensors, aircraft panels, and lightweight spacecraft structures, including deployable space booms and telescopes.

Now a new study has suggested how wrinkles can be increased or reduced by altering the curvature at the edge of a material.

Scientists first experienced the phenomenon of wrinkling while working with ultra-thin nanocrystalline diamond films, grown on a sheet of glass. They found that wrinkling was an unavoidable part of fabricating diamond windows.

Dr. Stoffel Janssens, the first author of the study and postdoctoral researcher in the MMM unit, said, “Diamond windows are complicated to make, but they have fascinating potential applications, including being used as a transparent structure upon which a cell culture can be grown and easily visualized.”

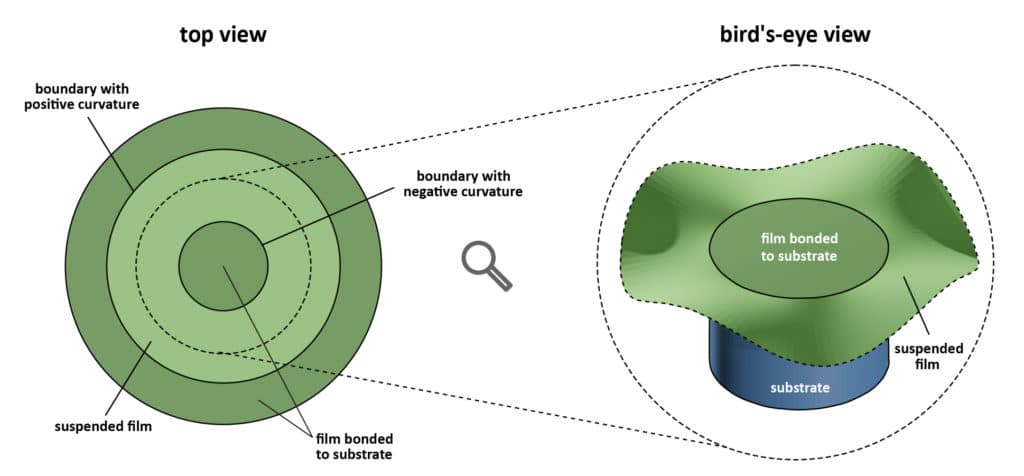

“The process of growing the nanocrystalline diamond film on top of the glass sheet involves heating and cooling the substrate, which causes the two layers to expand and contract by different amounts, generating stress in the layers. Then, when a hole in the glass substrate is made by lasers and acids to form a diamond window, the residual stress causes the now suspended portion of nanocrystalline diamond film, which is no longer bonded to the sheet of glass, to deform and wrinkle around the edge.”

Scientists realized that the diamond windows offer an excellent opportunity to comprehend better some of the physical factors that affect wrinkling.

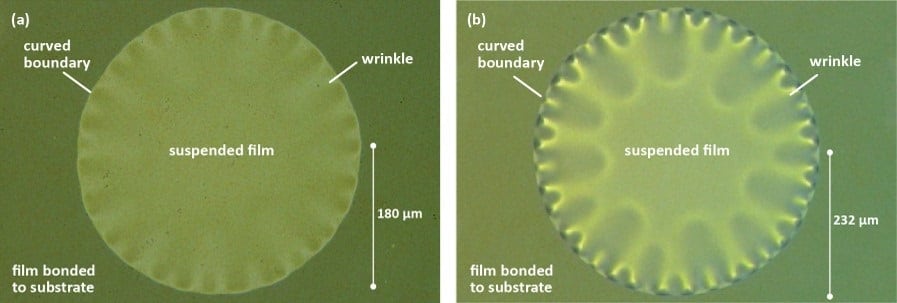

Hence, for the study, scientists created different sized diamond windows. They then evaluated the wavelength and number of wrinkles that formed in the suspended film around the curved edge of each diamond window.

They found that as the size of the diamond windows increased, reducing the curvature at the boundary between the bonded and suspended nanocrystalline diamond film, the density of wrinkles decreased. The wavelength of each wrinkle was longer.

Dr. Janssens said, “We also measured the level of strain across the diamond windows.”

“Measuring strain across a 2D material in a conventional way is very complicated and expensive, but we were able to devise a technique where we instead determined the surface profile of the diamond window — how high each point is — and then developed algorithms to retrieve the strain values.”

Using experimental results, scientists then developed a theoretical model that could be used to design devices with functional wrinkles or reduced wrinkling. By expanding on the experiments, the model suggested that the devices containing a negative curvature would see further reductions in wrinkling.

In a future study, scientists would like to create diamond windows in the shape of rings, rather than circles. While more challenging to fabricate, these structures have two boundaries between the suspended and attached portions of nanocrystalline diamond films – one with positive curvature and one with negative curvature – allowing the scientists to use experiments to explore the validity of their model further.

Journal Reference:

- Stoffel D. Janssens et al., Boundary curvature effect on the wrinkling of thin suspended films. DOI: 10.1063/5.0006164