MIT scientists have recently developed a printable structure that folds itself in a 3D structure when heated or immersed in water. The biggest advantage of these ‘Peel-And-Go’ printable structures is that they can involve a wider range of materials and more delicate structures.

Adding 3D-printed electronics means using some organic materials. These materials are very sensitive to moisture and temperature. Thus, if you have these electronics and parts and want to initiate folds in them, you wouldn’t want to dunk them in water or heat them. Doing this will degrade the electronics.

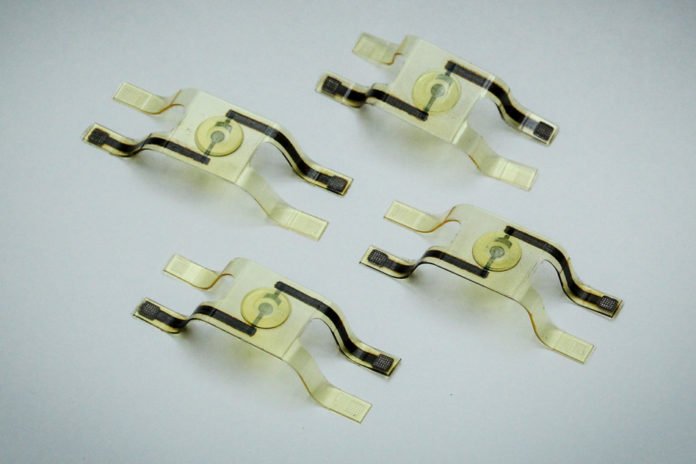

Scientists devised a prototype of a self-folding ‘Peel-And-Go’ printable structure to make this illustration a reality. The structure uses electrical leads and a polymer pixel that changes the material from transparent to opaque when applied voltage.

The device is a variation on the “printable goldbug” that scientists announced earlier of this year. It somewhat looks like the letter ‘H’. But each of the legs of the H folds itself in two different directions, producing a tabletop shape.

Scientists mainly utilized a new printer-ink material that expands after it solidifies. This is unusual because most printer-ink materials contract slightly as they solidify.

Printed devices are built up in layers. So scientists deposit their expanding material at precise locations on either the top or bottom few layers. The base layer sticks somewhat to the printer stage. This attachment efficiently holds the device flat as the layers are built up. The joints made from the new material start expanding when the device is peeled off the platform. Thus, the material bends itself towards the opposite direction.

Scientists wanted to develop an ink that yields more flexible printed components. While developing, scientists inadvertently hit upon one that expanded slightly after it hardened. They immediately recognized the potential utility of expanding polymers and began experimenting with modifications of the mixture. Hence, they built joints that would expand enough to fold a printed device in half.

Michael Dickey, a professor of chemical engineering at North Carolina State University, said, “This is exciting. It provides a way to create functional electronics on 3-D objects. Typically, electronic processing is done in a planar, 2-D fashion and thus needs a flat surface. The work here provides a route to create electronics using more conventional planar techniques on a 2-D surface and then transform them into a 3-D shape while retaining the function of the electronics. The transformation happens by a clever trick to build stress into the materials during printing.“

Scientists developed the ink that produces the most forceful expansion from the monomer isooctyl acrylate. When exposed to sunlight, its long molecular chains connect to each other and create a rigid thicket of tangled molecules.

Scientists then tried to add another layer on the top. They found the small chains of isooctyl started acylating on the top. Thus, the liquid layer sinks into the lower and creates a more rigid layer. Here, the longer chains exert an expansive force, which the adhesion to the printing platform temporarily resists.

According to scientists, a proper understanding of these ‘Peel-And-Go’ printable structures enables them to design material tailored to specific applications. These ‘Peel-And-Go’ printable structures resist the 1 to 3 % contraction typical of many printed polymers after curing.