When analyzing the comfort of the car, sound insulation is usually a determining factor. Reducing the rolling noise, coming from the engine or the rest of the exterior elements, has been one of the main concerns of the engineers working in this field, and in that objective, the materials used are usually something very important. But unfortunately, these materials are usually made of heavy materials, which compromises the final weight of the car.

That’s why, at the end of the last decade, Nissan engineers began working on material that was both more efficient and considerably lighter than the current ones. The result of their work is the structure they discovered and called it acoustic meta-material. The Japanese automaker is exhibiting the new lightweight sound insulation material – that can help make vehicle cabs quieter while also boosting energy efficiency – at CES 2020 in Las Vegas.

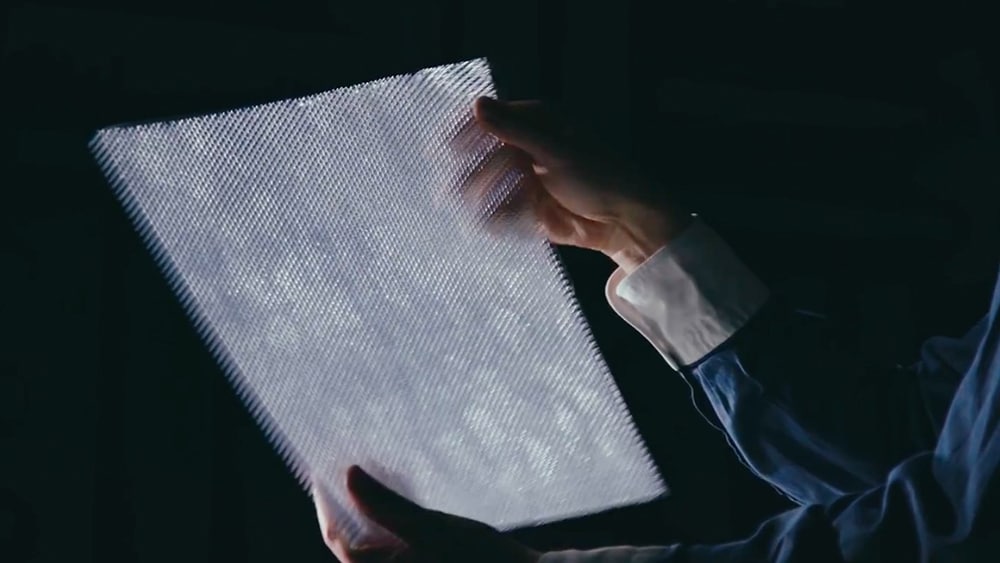

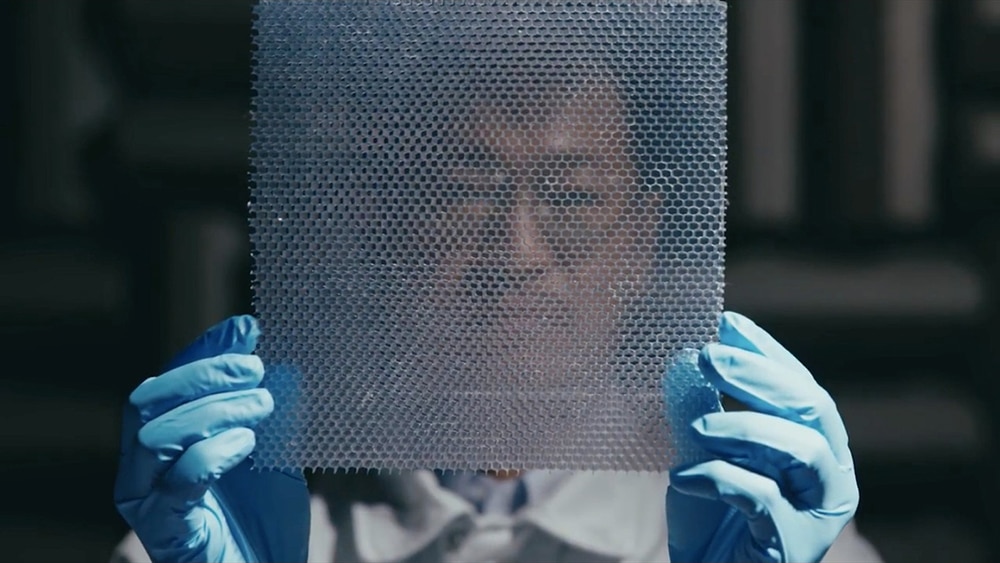

The invention was presented as a simple and innovative solution consisting of a lattice structure and plastic film. The combination “controls the vibration to limit the transmission of sound over a wide frequency range (500 to 1200 Hz) that generates road and engine sounds”.

Currently, heavy materials, such as rubber plates, are used for noise insulation of cars, but the new technology is about a quarter lighter. Meta-material guarantees the same level of sound insulation, even if it is 75% lighter than current solutions.

Since the “acoustic meta-material” has a simple structure, the new technology can get mass production and achieve the same or better price competitiveness than conventional soundproof materials. Therefore, in the future, it is expected that it will be widely used for vehicles.

As we have already indicated, Nissan has been working on this new product since 2008. At the time, meta-materials were used in high sensitivity antennas used in electromagnetic wave research. Nissan worked to extend the applicability of meta-materials technology to include sound waves, which led to the successful invention of a soundproofing material with high soundproofing characteristics, the press service of the company said.

Reducing the weight of the vehicle not only reduces the burden on the environment by increasing fuel efficiency and energy consumption but also helps to create cars that can be operated with great peace of mind. Besides, the quiet vehicle cabin makes travel time more comfortable and enhances enjoyment.