Steam turbines convert about 35 percent of a heat source into electricity. However, the machinery depends on moving parts that are temperature-limited. Heat sources higher than 2,000 degrees Celsius would be too hot for turbines. Scientists have looked into solid-state alternatives in recent years — heat engines with no moving parts that could work efficiently at higher temperatures.

Engineers at MIT and National Renewable Energy Laboratory (NREL) have designed a new heat engine with no moving parts. This heat engine- a thermophotovoltaic (TPV) cell- efficiently converts heat to electricity with over 40 percent efficiency.

Unlike traditional steam turbines that offer 35% efficiency, this new heat engine provides better performance.

Thermophotovoltaic (TPV) cell is similar to a solar panel’s photovoltaic cells. It captures high-energy photons from the heat source and converts them into electricity. This newly designed heat engine generates electricity from a heat source of between 1,900 to 2,400 degrees Celsius, or about 4,300 degrees Fahrenheit.

Using the TPV cells, scientists demonstrated the system’s main parts in separate, small-scale experiments. They are now working to integrate the parts to demonstrate a fully operational system. They hope to scale up the system to replace fossil-fuel-driven power plants and enable a fully decarbonized power grid supplied entirely by renewable energy.

Segun Henry, the Robert N. Noyce Career Development Professor in MIT’s Department of Mechanical Engineering, said, “Thermophotovoltaic cells were the last key step toward demonstrating that thermal batteries are a viable concept. This is a critical step on the path to proliferate renewable energy and get to a fully decarbonized grid.”

The TPV cells could be made from semiconducting materials with a particular bandgap like solar cells. If the material absorbs a high-energy photon, the material can kick an electron across the bandgap. The electron can then conduct and generate electricity without moving rotors or blades.

So far, TPV cells have achieved up to just 32 percent efficiency because they operate at lower temperatures. In this new study, scientists sought to design TOV cells that can capture higher-energy photons from a higher-temperature heat source. Compared with existing TPV designs, the resulting TPV cell does so with higher-bandgap materials and multiple junctions, or material layers.

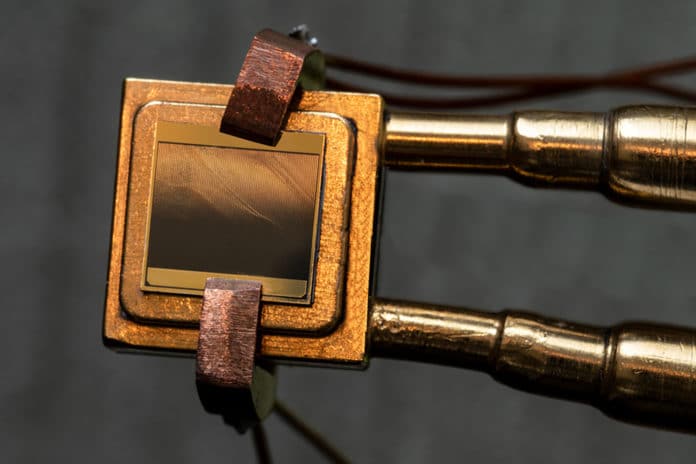

The cell is fabricated from three main regions: a high-bandgap alloy, which sits over a slightly lower-bandgap alloy, a mirror-like layer of gold. The first layer captures a heat source’s highest-energy photons and converts them into electricity, while lower-energy photons that pass through the first layer are captured by the second and converted to add to the generated voltage. Any photons that pass through this second layer are then reflected by the mirror back to the heat source rather than being absorbed as wasted heat.

The cells’ efficiency is determined by placing them over a heat flux sensor. The experiment involves exposing the cell to a high-temperature lamp. Later, scientists observed how the cell’s power efficiency changed with temperature when they varied the bulb’s intensity or temperature.

Scientists found that the cell maintained an efficiency of around 40 percent over 1,900 to 2,400 degrees Celsius.

Henry said, “We can get a high efficiency over a range of temperatures relevant to thermal batteries.”

“The cell in the experiments is about a square centimeter. For a grid-scale thermal battery system, the TPV cells would have to scale up to about 10,000 square feet (about a quarter of a football field) and operate in climate-controlled warehouses to draw power from huge banks of stored solar energy. He points out that infrastructure exists for making large-scale photovoltaic cells, which could also be adapted to manufacture TPVs.”

“There’s a huge net positive here in terms of sustainability. The technology is safe, environmentally benign in its life cycle, and can have a tremendous impact on abating carbon dioxide emissions from electricity production.”

Journal Reference:

- Latin, A., Schulte, K.L., Steiner, M.A. et al. Thermophotovoltaic efficiency of 40%. Nature 604, 287–291 (2022). DOI: 10.1038/s41586-022-04473-y