Most current urban vehicles are scaled-down versions of standard passenger cars. This imposes serious limitations on the safety, comfort, efficiency, dynamic performance, and, hence, customer acceptance of the vehicle.

In a new study by the University of Waterloo, scientists have proposed a new sophisticated wheel unit that could make the production of vehicles affordable for a wide variety of specialized purposes.

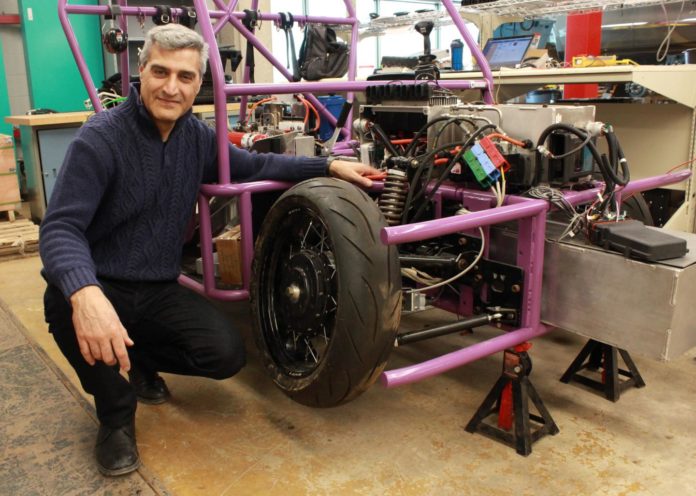

The wheel unit includes in-wheel suspension, an electrical in-wheel motor, a friction brake, a steering system, and a camber mechanism in a single module designed to be bolted to any vehicle frame. Moreover, there is a dual four-bar linkage mechanism has been designed to generate a virtual kingpin axis and provide an active camber.

This unit is expected to free manufacturers from making huge investments to develop those components from scratch. More importantly, it will enable the economical production of specialized vehicles in even small quantities.

Amir Khajepour, a mechanical and mechatronics engineering professor at Waterloo, said, “The idea is modularity and plug-and-play control capability. Our wheel unit, in a sense, is a full vehicle with only one wheel. All that’s missing is a body.”

Automotive researchers first applied the concept to electric, two-seater urban cars, which promise to ease congestion and reduce pollution but make up only a tiny fraction of sales because of high prices, space limitations, and safety concerns.

Mass-produced wheel units would significantly reduce production costs while also creating space for passengers that would otherwise be devoted to mechanical components such as steering columns.

To improve the stability of the tall, narrow cars, researchers also designed and prototyped the units – which weigh about 40 kilograms and have about 25 horsepower – to enable active wheel cambering or tilting.

Khajepour said, “Companies will be able to produce a smaller car that is cheaper, too. Right now, we are not there. You have to pay more to get a smaller car, to get less.”

Scientists are further planning to scale up the wheel unit, technically called a corner module, for large utility and commercial vehicles. According to them, this would lead to more cost-effective production of low-volume, specialized vehicles with customized bodies in fields including mining, forestry, and rescue operations.