CMFs, or foams made of hollow metal spheres in a metal matrix, are lightweight and super strong. They can be used in things like airplane wings and protective armor. CMF is also good at blocking high heat, better than regular metals like steel. This makes it useful for safely storing and transporting things like nuclear material or explosives.

But, to use CMF in many things, manufacturers need to weld different CMF parts together, and that’s been a challenge. There needs to be a solution when trying to weld CMF parts together. The heat used to melt the metal during welding makes it lose the good qualities of the CMF. Also, traditional welding methods fill in the tiny holes in CMF, making it not work as well. So, regular welding doesn’t go well with metal foams like CMF.

Scientists at North Carolina State University have found a way to weld composite metal foam (CMF) parts together without affecting the qualities that make CMF useful. The new welding technique allows for the joining of CMF components without compromising any of its desirable properties.

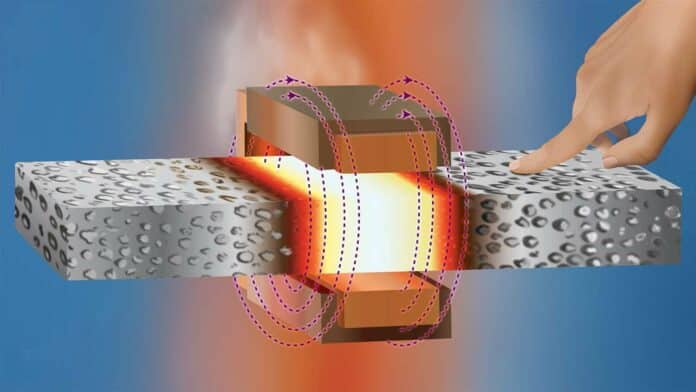

It’s called induction welding, and it uses an induction coil to create an electromagnetic field that heats the metal for welding.

Afsaneh Rabiei, corresponding author of a paper on the new research and professor of mechanical and aerospace engineering at NC State, said, “Because CMF is only 30-35% metal, the electromagnetic field can penetrate deeply into the material – allowing for a good weld.”

“The air pockets that make up the remaining 65-70% of the CMF serve to insulate the material against the heat. This allows induction welding to heat the targeted area for joining two pieces of CMF but prevents the heat from spreading out from the site of the join. That helps to preserve the CMF’s properties.”

“This is an important step forward because CMF’s properties make it attractive for a wide range of applications, but it’s essential to have a means of welding the CMF components without impairing the properties that make it attractive in the first place.”

Journal Reference:

- Afsaneh Rabiei, John Cance, Zubin Chacko. A Study on Welding of Porous Metals and Metallic Foams. Advanced Engineering Materials. DOI: 10.1002/adem.202301430