Wearable sweat sensors that can measure levels of salts, sugars, uric acid, amino acids, vitamins, and more complex molecules like C-reactive protein have been developed by Wei Gao, an assistant professor of medical engineering and investigator with the Heritage Medical Research Institute. It allows noninvasive continuous monitoring of physicochemical biomarkers for disease diagnosis and fitness tracking.

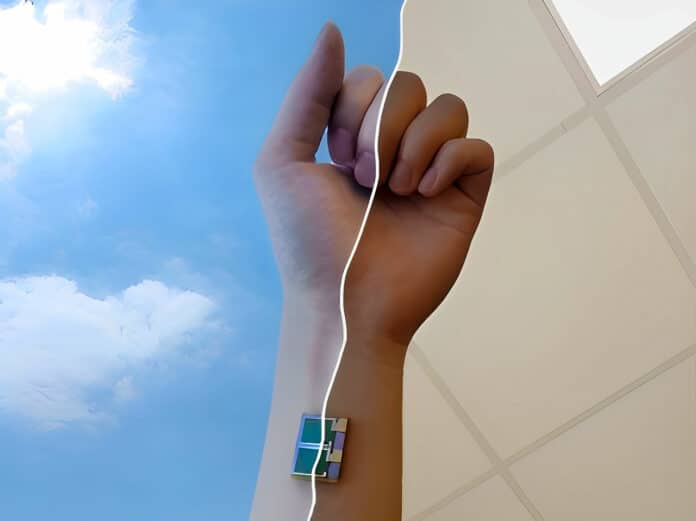

This technology can be used to assess certain health risks quickly. Gao has recently powered these wearable biosensors with a flexible solar cell with Martin Kaltenbrunner’s team at Johannes Kepler University Linz in Austria.

These sensors are powered by a flexible solar cell built of perovskite crystal, which is less expensive to produce than silicon due to the need for highly purified methods. Perovskite solar cell layers are up to 1,000 times thinner than silicon, making them “quasi-2D.” Furthermore, perovskite may be tailored to the spectra of many lighting sources, ranging from outdoor sunshine to various types of indoor lighting.

The flexible perovskite solar cell (FPSC) on Gao’s wearable sweat sensor boasts a record-breaking PCE of more than 31% under indoor light illumination. The spectral response of the FPSC corresponds closely with the standard interior lighting emission spectrum, making it particularly well-suited for indoor illumination.

Gao’s prior wearable sweat sensors were powered by lithium-ion batteries that had to be recharged with an external power source. Gao’s lab attempted to use silicon solar cells, which they discovered to be overly inflexible, inefficient, and dependent on solid lighting conditions in their search for a lighter, more sustainable source of electricity. They also tried extracting energy from human perspiration (a commonly available biofuel) and bodily motion. However, these could have been more stable or needed more effort.

Gao can make sweat sensors with FPSCs that can be worn continuously for 12 hours daily, measuring pH, salt, glucose, temperature, and periodic sweat rate without using batteries or a particular light source. Additionally, the wearable has space for additional detectors to simultaneously monitor more biomarkers as the power source grows lighter and less bulky.

The novel wearable sweat sensor is assembled in an origami style, with separate layers devoted to various processes. Its four main interdependent components are power management, iontophoresis, electrochemical measurement, data processing, and wireless communication. The sensor, which has dimensions of 20 x 27 x 4, can withstand the mechanical strain of being worn on the body.

Gao said, “Most of the elements of the sweat sensor, such as the electronics and the FPSC, are reusable. The only exception is the sensor patch, which is disposable, and it can be mass-produced at a low cost using inkjet printing.”

The substances the user wants to measure in their body can also be customized for these sensor patches. These solar-powered sweat sensors will be able to measure much more than current fitness and health trackers can once they are put to use. They can be used, for instance, to manage diabetes and find diseases, including heart disease, cystic fibrosis, and gout.

These sensors can determine a person’s baseline for substances like cortisol, hormones, or the metabolites of different foods and medications because they are noninvasive and can take several readings during brief times. Future departures from these baseline levels will provide a more accurate diagnosis than a test once the baseline levels for these drugs are known.

The Office of Naval Research for Space Health, the National Science Foundation, the National Institutes of Health, and a European Research Council Starting Grant all provided funding for the study.

Journal Reference:

- Min, J., Demchyshyn, S., Sempionatto, et al. An autonomous wearable biosensor powered by a perovskite solar cell. Nature Electronics. DOI: 10.1038/s41928-023-00996-y