Using a highly conductive type of two-dimensional material called MXene, scientists from Drexel University and Trinity College in Ireland have created ink for an inkjet printer. What’s more, the ink can be used to print flexible energy storage components, such as supercapacitors, in any size or shape.

Yury Gogotsi, Ph.D., a Distinguished University and Bach professor in Drexel’s College of Engineering, Department of Materials Science and Engineering, who studies the applications of new materials in technology, suggests that the ink created in Drexel’s Nanomaterials Institute is a significant advancement on both of these fronts.

Gogotsi said, “So far, only limited success has been achieved with conductive inks in both fine-resolution printing and high-charge storage devices. But our findings show that all-MXene printed micro-supercapacitors, made with an advanced inkjet printer, are an order of magnitude greater than existing energy storage devices made from other conductive inks.”

Scientists worldwide are consistently working to find ways from new, more conductive materials, like nanoparticle silver, graphene, and gallium; the challenge remains incorporating them seamlessly into manufacturing processes.

Babak Anasori, Ph.D., a research assistant professor in Drexel’s Department of Materials Science and Engineering, said, “Most of these inks can’t be used in a one-step process. Thus, an additive is required to hold the particles together and allow for high-quality printing. Because of this, after printing, an additional step is required — usually a thermal or chemical treatment — to remove that additive.”

“For MXene printing, we only use MXene in water or MXene in an organic solution to make the ink. This means it can dry without any additional steps.”

In materials science, MXenes are a class of two-dimensional inorganic compounds. These materials consist of a few atoms thick layers of transition metal carbides, nitrides, or carbonitrides. It can mix with liquids, like water and other organic solvents, while retaining conductivity.

Enlightening the properties, Drexel scientists have produced and tested it in various forms, from conductive clay to a coating for electromagnetic interference shielding to a near-invisible wireless antenna.

Adjusting the concentration to create ink for use in a commercial printer was a matter of time and iteration. The solvent and MXene concentration in the ink can be adjusted to suit different kinds of printers.

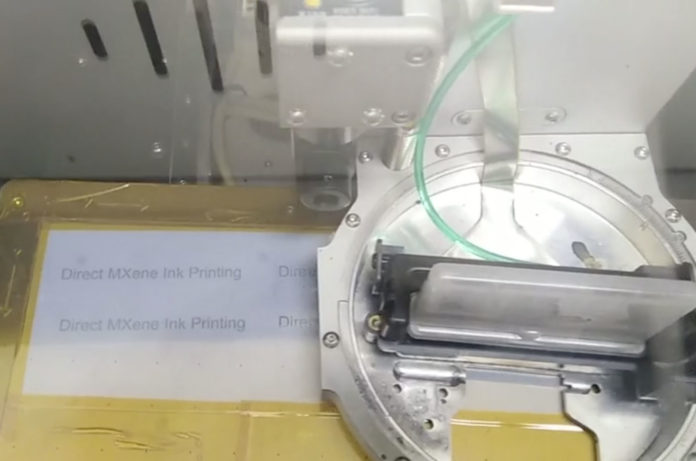

During experiments, scientists put the MXene ink to the test in a series of printouts, including a simple circuit, a micro-supercapacitor, and some text, on substrates ranging from paper to plastic to glass. While doing so, they found that print outcomes have consistent thickness. They also get surprised after seeing the ink’s ability to pass an electric current varied with its thickness.

The fascinating fact about the printouts is that they maintained their superior electric conductivity, which is the highest among all carbon-based conductive inks, including carbon nanotubes and graphene.

Anasori said, “This all amounts to a very versatile product for making the tiny components that perform important but often overlooked functions in our electronics devices — jobs like keeping the power on when the battery dies, preventing damaging electrical surges, or speeding the charging process. Providing a higher-performing material and a new way to build things with it could lead not only to improvements to our current devices but also the creation of entirely new technologies.”

“Compared to conventional manufacturing protocols, direct ink printing techniques, such as inkjet printing and extrusion printing, allow digital and additive patterning, customization, reduction in material waste, scalability, and rapid production. Now that we have produced an MXene ink that can be applied via this technique, we’re looking at a world of new opportunities to use it.”

In addition to Yury Gogotsi, PhD, and Babak Anasori, PhD, of Drexel University, John Zhang, Lorcan McKeon, Matthias Kremer, Sang-Hoon Park, Oskar Ronan, Andrés Seral-Ascaso, Sebastian Barwich, Cormac Ó Coileáin, Niall McEvoy, Hannah C. Nerl, Jonathan N. Coleman and Valeria Nicolosi from Trinity College participated in this research. The Drexel University portion of this research was funded by U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences.

The study is published in the journal Nature Communications.