By using a new method to print colloids such as polymer nanoparticles in highly ordered arrangements, scientists have united the principles of self-assembly and 3-D printing. Through this direct-write colloidal assembly process, scientists can now potentially build centimeter-high crystals, each made from billions of individual colloids.

Co-author Alvin Tan, a graduate student in MIT’s Department of Materials Science and Engineering said, If you blew up each particle to the size of a soccer ball, it would be like stacking a whole lot of soccer balls to make something as tall as a skyscraper. That’s what we’re doing at the nanoscale.”

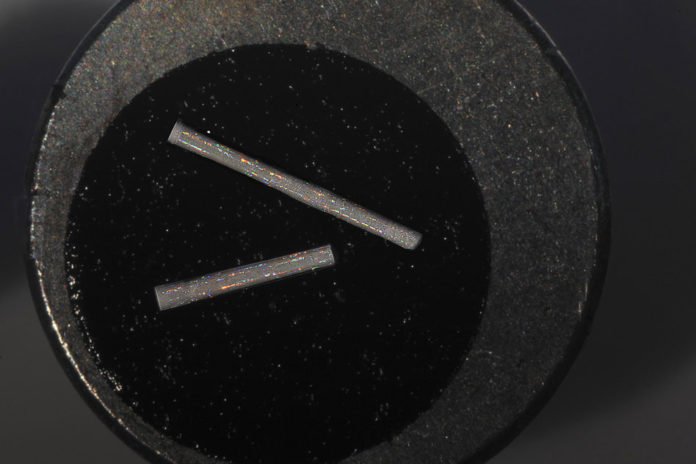

Using this method, scientists have printed various structures, such as tiny towers and helices, that interact with light in specific ways depending on the size of the individual particles within each structure.

Tan said, “If you could 3-D print a circuit that manipulates photons instead of electrons, that could pave the way for future applications in light-based computing that manipulate light instead of electricity so that devices can be faster and more energy efficient.”

Evaporating the liquid solvent of colloidal particles it can drive all particles altogether. Doing so causes them to assemble into ordered crystals and form structures that exhibit unique optical, chemical, and mechanical properties.

Until now, researchers have created procedures to evaporate and collect colloidal particles into thin films to form displays that filter light and make hues in light of the size and course of the arrangement of the individual particles. Be that as it may, as of not long ago, such colloidal assemblies have been constrained to thin films and other planar structures.

Scientists, for the first time, made it possible to build macroscale self-assembled colloidal materials. According to scientists, this technique can build any 3-D shape and be applied to an incredible variety of materials.

Scientists primarily build tiny three-dimensional towers of colloidal particles using a custom-built 3-D-printing apparatus consisting of a glass syringe and needle, mounted above two heated aluminum plates. The needle passes through a hole in the top plate and dispenses a colloid solution onto a substrate attached to the bottom plate.

The group equally warms both aluminum plates so that as the needle administers the colloid arrangement, the fluid gradually dissipates, leaving just the particles. The base plate can be pivoted and moved up and down to control the state of the general structure, like how you may move a bowl under a soft ice-cream container to make turns or whirls.

Graduate student Justin Beroz said, “As the colloid solution is pushed through the needle, the liquid acts as a bridge, or mold, for the particles in the solution. The particles “rain down” through the liquid, forming a structure in the shape of the liquid stream. After the liquid evaporates, the surface tension between the particles holds them in place, in an ordered configuration.”

During the prior demonstration, scientists worked with solutions of polystyrene particles in water and created centimeter-high towers and helices. Every one of these structures contains 3 billion particles. In ensuing preliminaries, they tried solution containing distinctive sizes of polystyrene particles and could print towers that reflected particular colors, contingent upon the individual particles’ size.

Beroz said, “By changing the size of these particles, you drastically change the color of the structure. It’s due to the way the particles are assembled, in this periodic, ordered way, and the interference of light as it interacts with particles at this scale. We’re essentially 3-D-printing crystals.”

There are a lot of things you can do with different kinds of particles ranging from conductive metal particles to semiconducting quantum dots, which we are looking into,”Tan says. “Combining them into different crystal structures and forming them into different geometries for novel device architectures, I think that would be very effective in fields including sensing, energy storage, and photonics.”