MIT engineers have recently came up with a darkest black material to date, that is 10 times blacker than anything that has previously been reported. They developed the material using vertically aligned carbon nanotubes, or CNTs- that grew on the surface of chlorine-etched aluminum foil.

The fascinating fact about this technology is, it absorbs more than 99.96% of light.

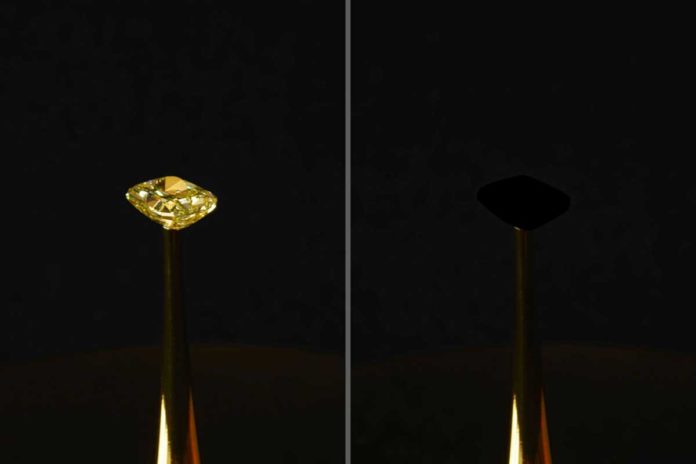

For this work, a 16.78 carat natural yellow diamond was covered utilizing another technique of producing carbon nanotubes (CNTs), recently measured to be the blackest black ever create, which causes the diamond to appear to disappear into an invisible void.

Brian Wardle, professor of aeronautics and astronautics at MIT said, “There are optical and space science applications for very black materials, and of course, artists have been interested in black, going back well before the Renaissance. Our material is 10 times blacker than anything that’s ever been reported, but I think the blackest black is a constantly moving target. Someone will find a blacker material, and eventually we’ll understand all the underlying mechanisms, and will be able to properly engineer the ultimate black.”

Engineers were actually experimenting with approaches to develop carbon nanotubes on electrically conducting materials, for example, aluminum, to help their electrical and thermal properties.

However, in endeavoring to develop CNTs on aluminum, they ran up against barrier, actually: an ever-present layer of oxide that coats aluminum when it is presented to air. This oxide layer acts as an insulator, blocking rather than conducting electricity and heat. As he cast about for approaches to evacuate aluminum’s oxide layer, they found a solution in salt, or sodium chloride.

For their experiments, engineers were only using salt and other pantry products, such as baking soda and detergent, to grow carbon nanotubes. In their tests, engineers noticed that chloride ions were eating away at aluminum’s surface and dissolving its oxide layer.

Soaking aluminiun foil in salt water removes the oxide layer. Engineers then transferred the foil to an oxygen-free environment to prevent reoxidation, and finally, placed the etched aluminum in an oven, where the group carried out techniques to grow carbon nanotubes via a process called chemical vapor deposition.

After removal of oxide layer, engineers were able to grow carbon nanotubes on aluminum, at much lower temperatures than they otherwise would, by about 100 degrees Celsius.

MIT postdoc Kehang Cui, now a professor at Shanghai Jiao Tong University said, “I remember noticing how black it was before growing carbon nanotubes on it, and then after growth, it looked even darker. So I thought I should measure the optical reflectance of the sample.”

When measured the amount of light reflected by light, engineers found that the material absorbed greater than 99.995 percent of incoming light, from every angle.

Wardle said, “CNT forests of different varieties are known to be extremely black, but there is a lack of mechanistic understanding as to why this material is the blackest. That needs further study.”

The researchers have published their findings today in the journal ACS-Applied Materials and Interfaces. They are also showcasing the cloak-like material as part of a new exhibit today at the New York Stock Exchange, titled “The Redemption of Vanity.”

The artwork, a collaboration between Brian Wardle, professor of aeronautics and astronautics at MIT, and his group, and MIT artist-in-residence Diemut Strebe.