Sometimes during surgery, even the most careful surgeons adjust the needle’s trajectory as they go along. Sometimes, the tissue may be tucked away beneath an organ or otherwise be very difficult to access. Such probing with a hard needle can delay operations and raise the possibility of injury or infection.

Charles Baur, an engineer at EPFL‘s Instant-Lab, working with et Lennart Rubbert1, a researcher at Strasbourg University, has developed a new kind of flexible needle (ARC) that addresses this problem. The trajectory of this innovative surgical needle can be corrected on the fly thanks to a flexible tip controlled with a simple button.

A button on the needle’s handle allows surgeons to correct the needle’s trajectory, enabling them to reach diseased tissue more quickly and, if needed, explore nearby tissue without pulling the hand out.

Baur said, “Today, the perception in hospitals is that the stiffer a needle is, the greater precision it can deliver. That’s because a stiff needle makes it easier for surgeons to move the instrument exactly as they want. This kind of stiffness can be found in the needle developed by Baur and his French colleague, thanks to the financing of the technology transfer office SATT Connectus, but coupled with a tip that surgeons can curve as needed. The whole system is mechanical.”

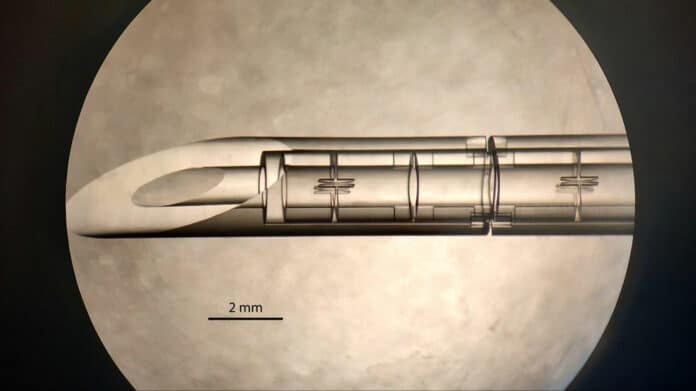

“Our needle has two tubes, one inside the other. When a surgeon slides the button, the inner tube translates and releases one, two, or three tiny segments that move in the direction indicated by the bevel of the needle and, therefore, by the orientation of the surgeon’s hand. For now, only the first few centimeters of the tip are flexible, but the system could be modified to extend that. We could also make some noncontiguous tip segments flexible while keeping the others stiff. That would allow an infinite number of possible trajectories.”

Baur, together with Rubbert, worked with FEMTOprint, a 3D-printing company for glass devices, to fabricate their needle, while Juan Verde2, a surgeon at the IHU of Strasbourg, helped them finalize the design. The scientists were able to create specialized needles with sizes of 0.9-4.5 mm to cover a variety of surgical applications because of the high-precision procedure.

Scientists tested two different types of materials: stainless steel and glass.

Baur said, “The stainless steel version is the most advanced because “glass technology is emerging and still requires development. Nevertheless, needles are intended for soft-tissue surgery, meaning they won’t have to withstand shocks.”

“We performed resistance tests in silicone which showed that the kind of glass we selected offers numerous benefits: it’s biocompatible, hard to deform, can be used with MRI machines, and doesn’t create reflections that could interfere with images of the area being operated on.”

“The flexible needles are almost ready for preclinical trials, and the engineers actively seek companies to partner with. It is possible to add additional functions to ensure specific surgical procedures such as electrostimulation, medication administration on demand, or biopsies, to name a few.”