The way by which wood develops is constrained by its genetic code, which gives it novel properties such as porosity, toughness, and torsional strength. However, wood has limitations with regards to processing. In contrast to metals and plastics, it can’t be melted and easily reshaped, and instead should be sawn, planed or bent.

Procedures which do include conversion to make items, for example, paper, card, and textiles destroy the underlying ultrastructure or engineering of the wood cells.

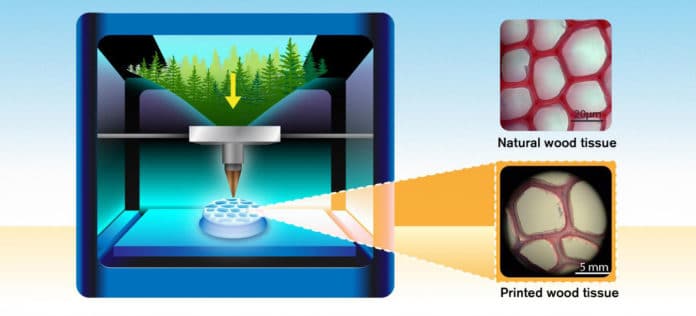

By previously converting wood pulp into a nanocellulose gel, scientists at Chalmers had just succeeded in making a sort of ink that could be 3D printed. Now, they have created a 3D printing platform which mimics wood biogenesis for the assembly of wood biopolymers into wood-like hierarchical composites.

It implies that now, the arrangement of the cellulose nanofibrils can be precisely controlled during the process, to reproduce the desirable ultrastructure of wood. Being able to manage the orientation and shape implies that they can catch those valuable properties of natural wood.

Professor Paul Gatenholm, who has led this research through the Wallenberg Wood Science Centre at Chalmers, said, “This is a breakthrough in manufacturing technology. It allows us to move beyond the limits of nature, to create newly sustainable, green products. It means that those products which today are already forest-based can now be 3D printed, in a much shorter time. Moreover, the metals and plastics currently used in 3D printing can be replaced with a renewable, sustainable alternative.”

The new technology opens up a whole new area of possibilities. Wood-based products could now be designed and ‘grown’ to order – at a vastly reduced timescale compared with natural wood.

Scientists have previously developed a model for an innovative packaging concept. They printed out honeycomb structures, with chambers in the middle of the printed walls, and after that managed to encapsulate solid particles inside those chambers. Cellulose has excellent oxygen barrier properties, which means this could be a promising technique for making water/air proof packaging for groceries or pharmaceuticals, for instance.

Paul Gatenholm, who has led this research through the Wallenberg Wood Science Centre at Chalmers, said, “Manufacturing products in this way could lead to huge savings in terms of resources and harmful emissions. Imagine, for example, if we could start printing packaging locally. It would mean an alternative to today’s industries, with heavy reliance on plastics and C02-generating transport. Packaging could be designed and manufactured to order without any waste.”

“The source material of plants is fantastically renewable so that the raw materials can be produced on site during longer space travel, or the moon or on Mars. If you are growing food, there will probably be accessible to both cellulose and hemicellulose.”

Scientists have already successfully demonstrated their technology at a workshop at the European Space Agency, ESA, and are also working with Florida Tech and NASA on another project, including tests of materials in microgravity.

The study is published in Applied Materials Today.