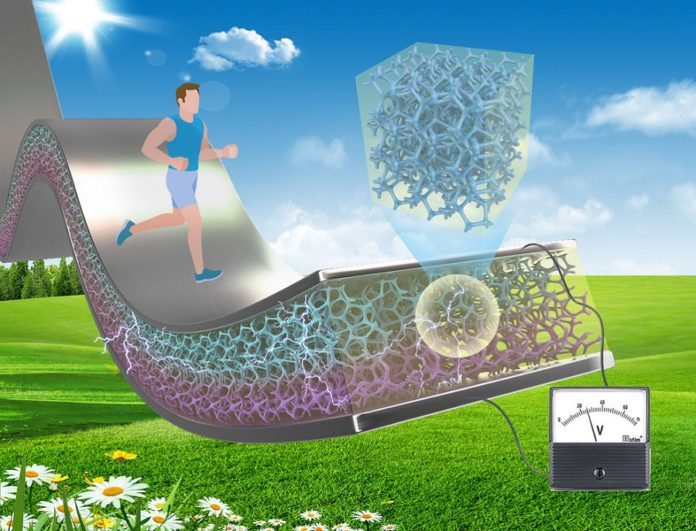

Penn State scientists have developed a piezoelectric ceramic foam that is expected to increase the ability to harvest mechanical and thermal energy over standard piezoelectric composites.

In health monitoring sensors, adding hard ceramic nanoparticles or nanowires to a soft, flexible polymer support could increase the flexibility. But, these materials are relatively inefficient, because upon mechanical loading the mechanical energy is largely absorbed by the bulk of the polymer, with a very small fraction transferred to the piezo nanoparticles. While adding more ceramic would increase the energy efficiency, it comes with the tradeoff of less flexibility.

Almost 3 decades ago, the late Penn State materials scientist Bob Newnham came up with the concept that the connectivity of the piezo filler determined the efficiency of the piezoelectric effect. According to him, a three-dimensional material would be more efficient than zero-dimensional nanoparticles, one-dimensional nanowires or two-dimensional films, because the mechanical energy would be transported directly through the three-dimensional material instead of dissipating into the polymer matrix.

Qing Wang, professor of Penn State said, “Everybody in the ceramic community knew of his approach, but how to achieve that 3-D structure with a well-defined microstructure remained a mystery.”

Now, scientists found that the small polyurethane foam dusting sheet can be a secret ingredient to solve the mystery. The little uniform projections on the sheet go about as a layout for framing the microstructure of the piezoelectric ceramic. The specialists applied the ceramic to the polyurethane sheet as suspended nanoparticles in solution.

At the point when the format and arrangement are warmed to a sufficiently high temperature, the sheet burns out and the solution crystalizes into a strong 3-D microform foam with uniform holes. They then fill the openings in the ceramic foam with the polymer.

Wang said, “We see that this 3-D composite has a much higher energy output under different modes. We can stretch it, bend it, press it. And at the same time, it can be used as a pyroelectric energy harvester if there is a temperature gradient of at least a few degrees.”

Sulin Zhang, professor of engineering science and mechanics, Penn State aid, “We were able to show theoretically that the piezoelectric performance of nanoparticle/nanowire composites is critically limited by the large disparity in stiffness of the polymer matrix and piezoceramics, but the 3-D composite foam is not limited by stiffness. This is the fundamental difference between these composite materials, which speaks to the innovation of this new 3-D composite. Our extensive simulations further demonstrate this idea.”

Now, scientists are working with lead-free and more environmentally friendly alternatives to the current lead-zirconium-titanate ceramic.

Additional authors of the study include Guangzu Zhang, formerly in Wang’s group and now at Huazhong University of Science and Technology, China; and Peng Zhao, a doctoral student in Zhang’s group. Other contributors are Xiaoshin Zhang, Kuo Han, Tiankai Zhao, Yong Zhang, Chang Kyu Jeong and Shenglin Jiang.

Journal Reference

- Guangzu Zhang, Peng Zhao, Xiaoshan Zhang, Kuo Han, Tiankai Zhao, Yong Zhang, Chang Kyu Jeong, Shenglin Jiang, Sulin Zhang, Qing Wang. Flexible three-dimensional interconnected piezoelectric ceramic foam based composites for highly efficient concurrent mechanical and thermal energy harvesting. Energy & Environmental Science, 2018; DOI: 10.1039/C8EE00595H

- Guangzu Zhang, Peng Zhao, Xiaoshan Zhang, Kuo Han, Tiankai Zhao, Yong Zhang, Chang Kyu Jeong, Shenglin Jiang, Sulin Zhang, Qing Wang. Flexible three-dimensional interconnected piezoelectric ceramic foam based composites for highly efficient concurrent mechanical and thermal energy harvesting. Energy & Environmental Science, 2018; DOI: 10.1039/C8EE00595H