MIT scientists have recently developed intelligent textiles that are comfortable and form-fitting fabric. This smart textile senses how its users are moving. It can recognize its wearer’s activities, like walking, running, and jumping.

They used a particular type of plastic yarn and melted it. This process is known as thermoforming. In doing so, scientists could significantly improve the precision of pressure sensors woven into multilayered knit textiles, which they call 3DKnITS.

Using this process, they created a smart shoe and mat. Later, they measured and interpreted data from the pressure sensors in real-time operating newly developed hardware and software systems. With an accuracy rate of roughly 95%, the machine-learning algorithm anticipated the movements and yoga positions a person would make while standing on the smart textile mat.

To fabricate their smart textile, scientists took advantage of digital knitting technology. The technology allows rapid prototyping and can be easily scaled up for large-scale manufacturing.

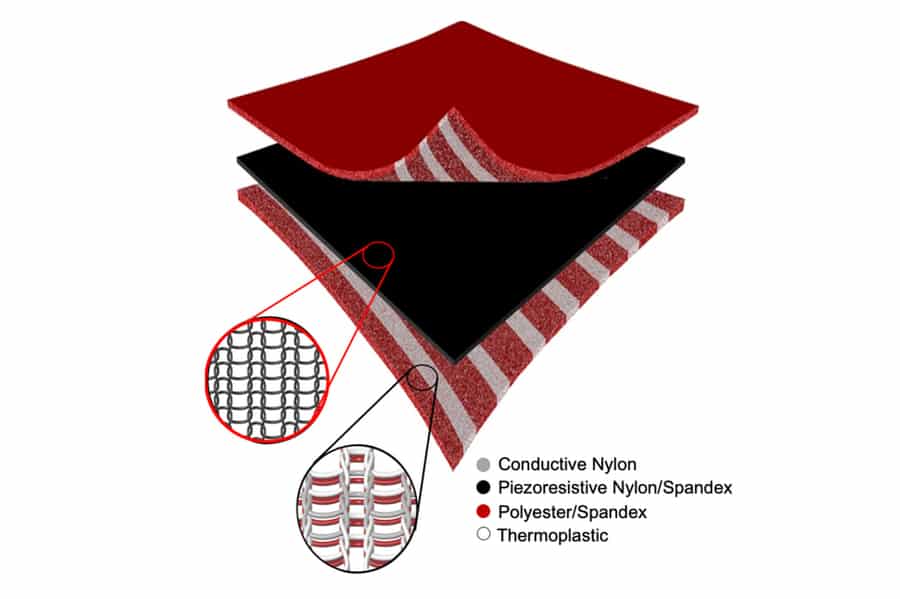

The digital knitting machine weaves layers of fabric with rows of standard and functional yarn. The multilayer knit fabric is made of a piezoresistive knit that changes resistance when squeezed, sandwiched between two layers of conductive yarn knit. The machine stitches this useful yarn in horizontal and vertical rows across the fabric in accordance with a pattern. A pressure sensor is made where the functional fibers cross.

But yarn is soft and pliable, so the layers shift and rub against each other when the wearer moves. This generates noise and causes variability, making the pressure sensors much less accurate.

Irmandy Wicaksono, a research assistant in the MIT Media Lab, came up with a solution to this problem. He watched workers making sneakers using thermoplastic yarns that would start to melt when heated above 70 degrees Celsius, which slightly hardens the textile so it can hold a precise shape.

He decided to try incorporating melting fibers and thermoforming into the smart textile fabrication process.

He said, “The thermoforming solves the noise issue because it hardens the multilayer textile into one layer by squeezing and melting the whole fabric together, improving accuracy. That thermoforming also allows us to create 3D forms, like a sock or shoe, that fit the precise size and shape of the user.”

After this, he required a system to precisely process pressure sensor data. Since the fabric is knit as a grid, scientists developed a wireless circuit that scans through rows and columns on the textile and measures the resistance at each point.

They also created a system that displays pressure sensor data as a heat map. Those images are fed to a machine-learning model, which is trained to detect the user’s posture, pose, or motion based on the heat map image.

According to scientists, their smart textile could be useful, especially in health care and rehabilitation. For example, it could be used to produce smart shoes that track the gait of someone who is learning to walk again after an injury or socks that monitor pressure on a diabetic patient’s foot to prevent the formation of ulcers.

Scientists are now exploring more creative applications. In collaboration with a sound designer and a contemporary dancer, they developed a smart textile carpet that drives musical notes and soundscapes based on the dancer’s steps to explore the bidirectional relationship between music and choreography.

Eric Berkson, assistant professor of orthopaedic surgery at Harvard Medical School and sports medicine orthopaedic surgeon at Massachusetts General Hospital, who was not involved in this research, said, “It’s always amazing to see technology advance in ways that are so meaningful. It is incredible to think that our clothing, an arm sleeve or a sock, can be created in ways that its three-dimensional structure can be used for sensing. In the medical field and orthopedic sports medicine specifically, this technology provides the ability to detect better and classify motion and recognize force distribution patterns in real-world (out of the laboratory) situations. This thinking will enhance injury prevention and detection techniques and help evaluate and direct rehabilitation.”

Journal References:

- Irmandy Wicaksono, Joseph A. Paradiso et al. 3DKnITS: Three-dimensional Digital Knitting of Intelligent Textile Sensor for Activity Recognition and Biomechanical Monitoring.

- Irmandy Wicaksono, Don Derek Haddad, and Joseph Paradiso. Tapis Magique: Machine-knitted Electronic Textile Carpet for Interactive Choreomusical Performance and Immersive Environments. C&C ’22: Creativity and Cognition. DOI: 10.1145/3527927.3531451