Researchers at the Skolkovo Institute of Science and Technology (Skoltech) have recently found a way to significantly enhance the efficiency of both power plants and jet engines, leading to increased electricity production and reduced fuel consumption. They have proposed a range of new ceramic materials that could be used as metal coatings to boost gas turbine efficiency.

If further experimental tests prove successful, these coatings will enable power plants to produce more electricity and jet planes to consume less fuel. The researchers behind this discovery also aim to continue the search for other potential candidates with even better properties.

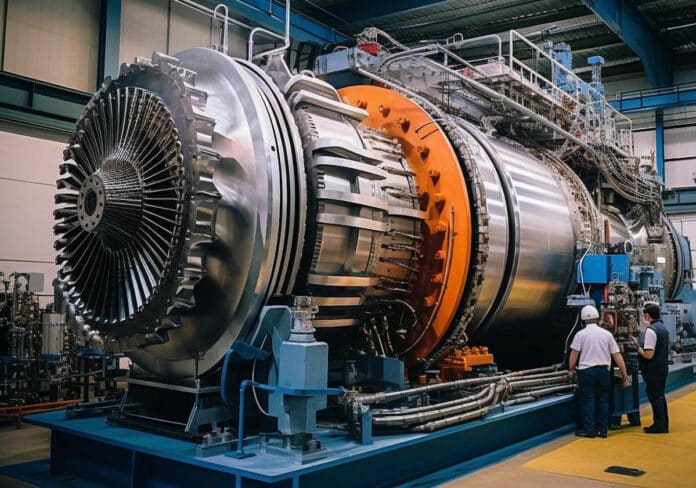

Thermal barrier coatings protect turbine blades in power plants and jet engines. The blades themselves are made of nickel-based superalloys known for their high-temperature strength, toughness, and resistance to degradation. However, these parts can soften and melt under the turbine’s harsh operating conditions.

Protective coatings are needed to operate turbines at higher temperatures, thereby increasing efficiency without compromising the turbine blades’ integrity.

“Thermal barrier coatings are nowadays made of yttria-stabilized zirconia, but if a material with better properties were used instead, that would allow you to get more useful power out of the turbine,” says study co-author Professor Artem R. Oganov, who heads the Material Discovery Laboratory at Skoltech.

“To find such materials, you first have to come up with candidates whose properties you predict computationally. We have tested a range of methods and determined the best one for calculating the relevant material properties, particularly thermal conductivity. In the paper, we list some promising candidates, and we’ll keep on looking.”

A material used for thermal barrier coatings must meet several requirements. Firstly, it should have an extremely high melting point and a very low thermal conductivity. The latter property can be difficult to determine as it is dependent on complex “anharmonic” effects in crystals.

When heated, the material should also expand at approximately the same rate as the superalloy, or it will flake off the surface. Additionally, it should remain stable without undergoing any phase transitions between room temperature and the operating temperature of the turbine, as it would cause the coating to crack.

In addition, the material should be able to withstand the effects of dust particles and oxygen at high temperatures while preventing oxygen ions from reaching the underlying metal and oxidizing it.

“While we did calculate the other properties, the crux of the problem is predicting thermal conductivity,” says study co-author, Skoltech PhD student Majid Zeraati. “We showed such predictions are computationally feasible and reasonably accurate with homogeneous nonequilibrium molecular dynamics simulations. This proves somewhat unexpected, as such simulations involve massive computations and extensive statistics, resulting in high computational complexity. Nevertheless, we managed to simplify the method by supplementing it with machine learning potentials: That is, the interactions between the atoms were predicted using artificial intelligence rather than being directly calculated.”

The Skoltech team is committed to continuing their search for even more efficient materials, aiming to optimize turbine technology further. Their study highlights some promising materials that can potentially surpass yttria-stabilized zirconia, the current standard for thermal barrier coatings. These materials include yttrium niobate, BaLaMgTaO6, BaLaMgNbO6, and seven others.

The team says this research represents a significant step towards achieving more sustainable and efficient energy production and could have a substantial impact on the aerospace industry as well.

Journal reference:

- Majid Zeraati, Artem R. Oganov, Tao Fan, and Sergey F. Solodovnikov. Searching for low thermal conductivity materials for thermal barrier coatings: A theoretical approach. Physical Review Materials, 2024; DOI: 10.1103/PhysRevMaterials.8.033601