The optical state of a material affects its visual appearance and its possible applications. In principle, it is impossible to switch material from a reflective optical state to a fully transparent one.

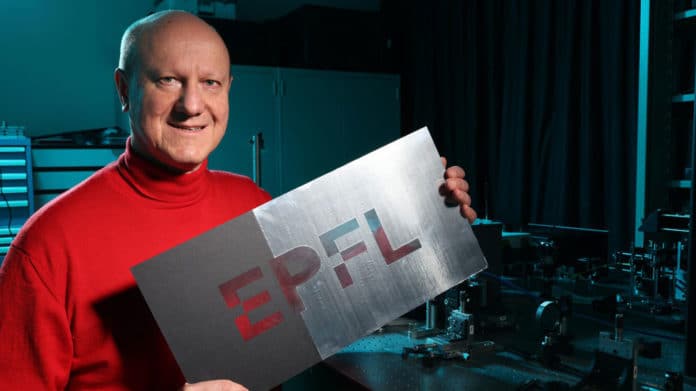

EPFL scientists recently developed a new type of printing process that turns Guttenberg’s concept on its head. Instead of depositing the material, the method involves removing the material.

According to scientists, their method could be particularly useful for printing banknotes and ID documents.

Scientists initially wanted to develop a material that absorbs light completely. They created a material composed of nanometers thick three layers – first aluminum, then magnesium fluoride (a dielectric compound), and finally chrome – sitting on a Plexiglas substrate.

The result is a black surface that absorbs all light waves.

Martin said, “Black is a really hard color to obtain. You usually end up with something that has either bluish or violet undertones. But in our case, the black we obtained was truly black. That means our material can capture 100% of the light it’s exposed to.”

Sebastian Mader, the Ph.D. student who led the project, wanted to see what would happen if he removed the top layer of the material: the chrome.

He said, “Once I did that, all that was left was the dielectric compound and the aluminum. Together, these two compounds form a perfect mirror. They reflect all wavelengths of light, absorbing none of it.”

“That gave us a fully transparent surface.”

Using a laser, scientists were able to remove the individual layers precisely.

Martin said, “The longer we left the laser on a given spot, the more material is removed. We basically ‘drew’ lines of transparency rather than lines of color.”

“Their new method could be especially useful in security applications and for printing banknotes. Contrast is significant for our eyes, and since our method can produce both fully black and fully transparent areas, we can generate a lot of contrast.”

“For instance, we can draw white letters on a black background, making the letters very easy to read.”

Journal Reference:

- Sebastian Mader et al. Engineering multi-state transparency on demand. DOI: 10.37188/lam.2021.026