Another bit of innovation at the University of Plymouth is helping analysts build up a working skin substitute that can emulate functional human skin.

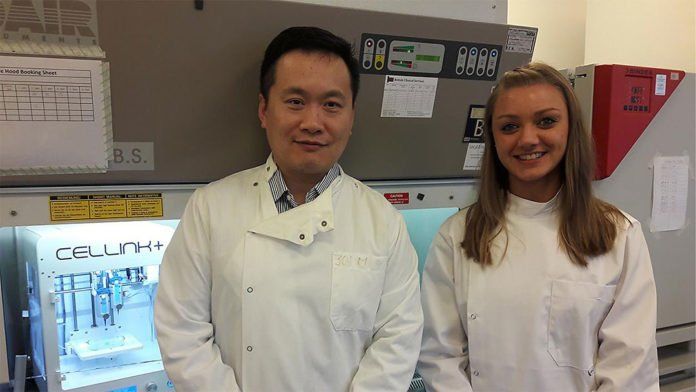

The 3D bioprinter will empower Dr. Bing Hu and his group to test whether a portion of the current coastal plants in Cornwall could have ground-breaking healthy skin applications.

Dr. Hu said, “Major cosmetic brands have integrated seaweed and coastal plant extracts into high-end products. However, in Cornwall, high-value coastal plants and seaweed extracts for cosmetics use are still underdeveloped due to lack of relevant research.”

Although Cornwall and the Isles of Scilly have a long tradition of growing high-value specialty crops and plants, advances in growing technology have removed much of Cornwall’s advantage of early cropping seasons, which were once very lucrative. If the project can prove that some of these native Cornish coastal plants and seaweeds can be successfully incorporated into new skincare treatments, it could increase the value of the crops that are grown by Cornish growers and help improve incomes.

Dr. Hu said, “The sector is very preliminary stages. There are big gaps in our understanding and the precise ways in which such ‘marine’ products aid the skin still largely unknown.”

“But the proximity to the sea of Cornwall and the Isles of Scilly, combined with the unique climate of the area, means certain types of plants have always thrived here – and a range of them could have as-yet-untapped potential.”

The technology replicates skin with immense degrees of reality at that point makes development, so yielding nonstop and continuous bits of knowledge into tissue and cell events, accordingly giving bits of knowledge into the aging procedure and permitting distinctive materials’ anti-wrinkling adequacy to be tried.

Moreover, it could spin out into new opportunities, potentially becoming a globally used, standardized “Organ-on-a-Chip” model for simulating human skin for testing in the cosmetics and health sectors. It is hoped that one day, it could even print live skin.

Ph.D. student Charlotte Illsley said, “Skin is the largest organ in the body accounting for around 15 percent of adult body weight. It is made up of three layers – epidermis, dermis, and hypodermis with each component performing specialist functions. If any of these components malfunction, it usually results in undesirable conditions from a rash to cellulitis or even cancer.”

“The development of skin equivalent systems allow for the study of wound healing and regeneration alongside drug delivery and skin care testing. There is currently a massive market for skin-engineered substitutes, but to the best of our knowledge, there is currently no skin model that is able to mimic all aspects of the skin. The 3D bioprinter is a great start to helping us on the long road of testing to enable this to happen by combining with an Organ-on-a-Chip skin platform that is currently under development in our school.”

Dr Bing Hu, who is running the project within the University’s Institute of Translational and Stratified Medicine (ITSMed) continued: “We will use this skin substitute as a platform for testing products from a number of SMEs in Cornwall, to help develop and screen their products for anti-aging properties that could be used for the UV protection of skin and curing irritating conditions such as dermatitis.”

“The demand for natural, extract-based, organic cosmetics and personal care is very much growing and we’d like to see Cornish SMEs capitalize on that market.”

“At present, worldwide, there is still a long way to go in terms of establishing exactly how these ingredients work and there is an urgent need to understand more about – and prove – the biological function of Cornish seaweeds, coastal plants and sea salt on human skin. Such proof of biological functioning is essential if SMEs and growers in West Country businesses are to take on the international giants.”

Professor Christopher Tredwin, Head of Peninsula Dental School, concluded: “It’s fantastic that Peninsula Dental School is collaborating with Cornish businesses to help identify how local resources could help to bring more governmental and private investments to the region. In addition to this work, the 3D bioprinter technique could be further transmitted into the other research fields in the Faculty of Medicine and Dentistry – which is a very exciting prospect.”