Generally, mono-and co-culture bioprocess applications depend on enormous scale suspension fermentation technologies that are not effectively convenient, reusable, or reasonable for on-demand production.

Now, a team of engineers has developed a hydrogel system for producing medicines and chemicals and preserve them using portable “biofactories.” The methodology could help individuals in remote villages or on military missions, where the absence of medicals, doctor’s offices, or even fundamental refrigeration makes it difficult to access critical medicines and other small-molecule compounds.

Alshakim Nelson, an assistant professor of chemistry at the University of Washington, said, “We expect these developments to afford new technologies for on-demand production of small-molecule and peptide products in the future. This technology will be especially applicable in remote or isolated areas where space and resources are limited, which could include manned space missions or personalized medications.”

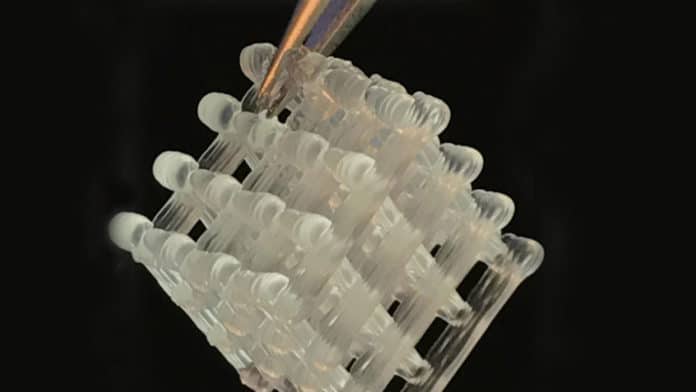

The new framework successfully embeds microbial biofactories into the solid scaffold of a hydrogel, taking into consideration portability and enhanced generation.

It is the first hydrogel-based system to organize both individual microbes and consortia for in-the-moment production of high-value chemical feedstocks utilized for procedures, for example, fuel and pharmaceutical generation. Products can be delivered within two or three hours to a couple of days.

The hydrogel system has the best fermentation capacity even after freeze-drying. During testing, the result f the freeze-drying somewhat resembles an ancient mummy, shriveled up but well-preserved. To revive the system, scientists added water, sugar, and other essential nutrients, and the cells could resume production just as effectively as before the preservation process.

Also, this hydrogel system can combine multiple different organisms, called consortia, together in a way that outperforms traditional, large-scale bioreactors. For example, if one set of enzymes works best in the bacteria E. coli, while the other works best in budding yeast, the two organisms can work together to more efficiently go straight to the product. The research team tested both of these organisms.

Along with this, the system can efficiently perform multitasking: 1. It can keep different types of cells separated while they grow. 2. Prevent one from taking over and killing off the others.

Hal Alper, a professor of chemical engineering at the University of Texas, said, “This technology can be applied to a wide range of products and cell types. We see engineers and scientists being able to plug and play with different consortia of cells to produce several products that are needed for a specific scenario. That’s part of what makes this technology so exciting.”

Co-lead authors on the paper are UW graduate student Trevor Johnston and University of Texas graduate student Shuo-Fu Yuan. Co-authors are James Wagner and Xiunan Yi at the University of Texas, former UW postdoctoral researcher Abhijit Saha, and UW graduate student Patrick Smith. The research was funded by the Camille and Henry Dreyfus Foundation, the University of Washington, and the Royalty Research Fund.

The paper describing the approach is published in the journal Nature Communications.