Most desalination plants use Reverse Osmosis for water filtration. In this technique, water flows through the membranes to remove salt. But the real challenge is the fouling of these membranes by microorganisms.

MIT scientists now come with a different approach in order to improve the efficiency of RO plants.

Generally, the fouling occurs due to the high pressure required by RO. But, scientists suggest, this is not the case and suggests a new approach to reducing it.

The high pressure in an RO framework packs the microbial mats, that develop on the films. This structure made the fouling hard to remove. In low-pressure forward osmosis (FO) systems, which are less energy-efficient but more fouling-resistant, the supposedly looser mat is thought to be easier to clean off.

Courtesy of the researchers

Emily Tow, PhD ’17 said, “However, these microbial mats are generally full of water, which does not compress under RO pressures, so “there is no good reason why high pressure should worsen fouling. Comparing the microbes to a scuba diver, there’s a lot of pressure at the bottom of the ocean, but it doesn’t make you stick to the seafloor.”

“But if pressure doesn’t matter, and the flow rates through FO and RO systems are similar, what could account for the disparity in fouling resistance?”

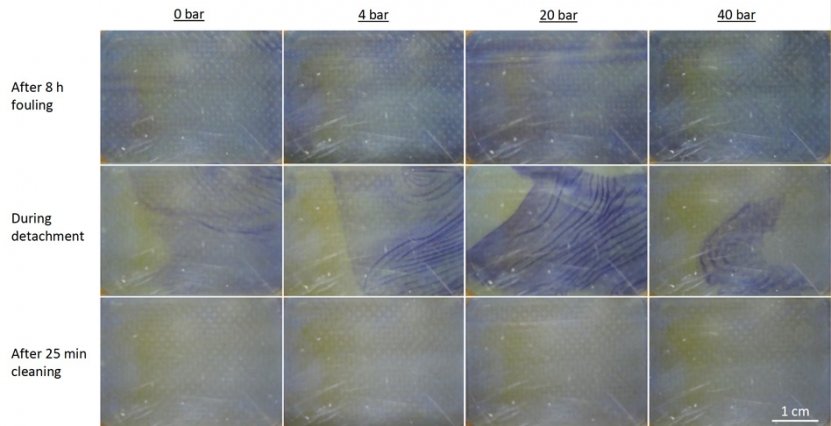

Scientists isolated the effects of pressure from those of other differences between FO and RO. They operated an FO system, which uses osmosis to pull water through membranes, at a range of pressures up to 40 atmospheres. They then measured fouling rates and cleaning outcomes at various pressures. There was no effect of pressure.

Abdul Latif Jameel Professor of Water and Food said, “The observation that forward osmosis membranes are easier to clean is fairly robust. But the study shows that FO’s fouling resistance is not intrinsic to its low pressure. The difference must be related to other factors that could potentially be transferable to RO. It needs to be understood.”

“The hope is that with further work, this could make it easier to clean RO membranes. Currently, mitigating membrane fouling is a major part of non-energy operating expenses of an RO plant, which accounts for about a quarter of the cost of desalinated water. Any improvement in fouling resistance could significantly impact water cost.”

It’s possible that the difference in how fouling affects RO and FO membranes has to do with the membrane’s salt filtering layer.

Tow explained, “In FO, the membrane in which the support layer and the concentrated solution affects water flow, through which foulants occur on membrane’s surface.”

MIT Professor John H. Lienhard V said, “Improving the ability to clean used membranes could affect not only water cost but also the reliability of desalination plants. Shutdowns because of an algal bloom can sometimes interrupt the supply of water for days or weeks on end.”

Richard L. Stover, director of the International Desalination Association, said, “The new mechanisms the researchers propose qualitatively explain the fouling resistance observed in FO systems, providing clear direction and outstanding context for future research.”