In the US, most of the vehicles like car and trucks runs on 90 percent gasoline and 10 percent ethanol. Although most of the fuel additive ethanol used in the U.S. is made from fermented corn. Almost 14 billion gallons of ethanol consumed annually by American drivers requires millions of acres of farmland.

Having concern over this, scientists carbon dioxide into higher-value chemicals and fuels without byproducts.

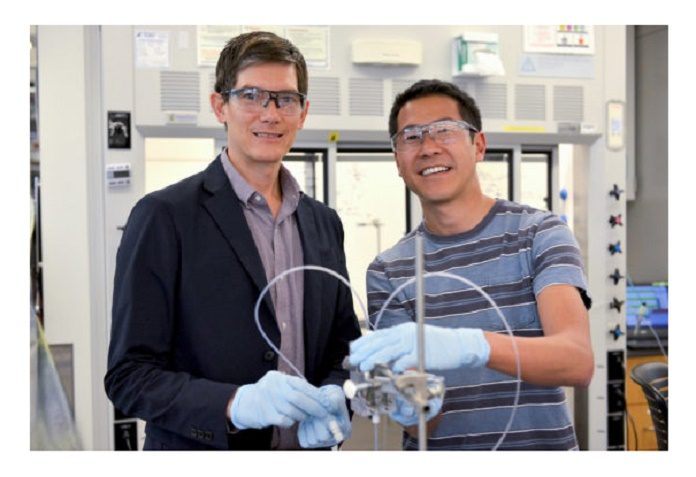

Credit: Mark Shwartz/Stanford University

Scientists actually want to make the copper catalyst that selectively converts carbon dioxide into higher-value chemicals and fuels without byproducts. To do so, they primarily need to understand the working of these catalysts.

Thomas Jaramillo, an associate professor of chemical engineering at Stanford said, “One of our long-range goals is to produce renewable ethanol in a way that doesn’t impact the global food supply.”

“Copper is one of the few catalysts that can produce ethanol at room temperature. You just feed it electricity, water, and carbon dioxide, and it makes fuel additive ethanol. The problem is that it also makes 15 other compounds simultaneously, including lower-value products like methane and carbon monoxide. Separating those products would be an expensive process and require a lot of energy.”

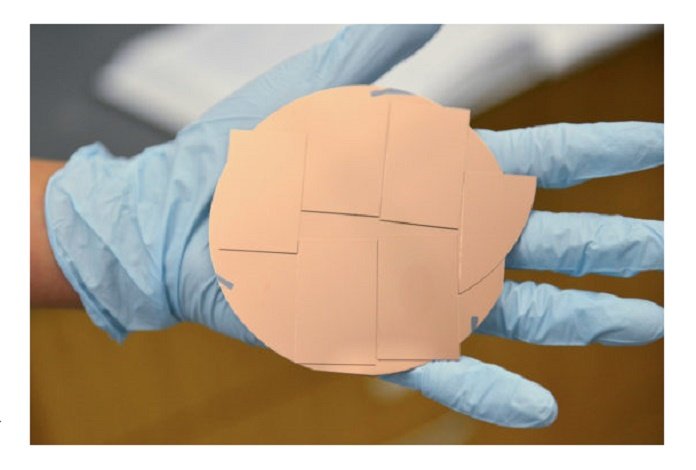

For the PNAs study, scientists three samples of crystalline copper, known as Copper (100), Copper (111) and Copper (751). Copper (100), (111) and (751) look virtually identical. But they have major differences in the way they arranged their atoms on the surface. They then use these numbers to describe the surface geometries of single crystals.

Christopher Hahn, an associate staff scientist at SLAC said, “The essence of our work is to understand how these different facets of copper affect electrocatalytic performance.”

In this study, scientists developed a novel way to grow single crystal-like copper on top of large wafers of silicon and sapphire. This approach resulted in films of each form of copper with a 6-square centimeter surface, 600 times bigger than typical single crystals.

Scientists then placed 3 large electrodes in water to compare the electrocatalytic performance. They then exposed the electrodes to carbon dioxide gas and applied some voltage potential to generate an electric current.

When they applied the voltage, they found that the electrodes made of copper (751) were far more selective to liquid products, such as fuel additive ethanol and propanol.

Jaramillo said, “The eye on the prize is to create better catalysts that have game-changing potential by taking carbon dioxide as a feedstock and converting it into much more valuable products using renewable electricity or sunlight directly.”

“We plan to use this method on nickel and other metals to further understand the chemistry at the surface. We think this study is an important piece of the puzzle and will open up whole new avenues of research for the community.”

Now, scientists are working to develop a technology capable of selectively producing carbon-neutral fuels and chemicals at an industrial scale.