Researchers from the Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) have built up an approach to print 3D structures made completely out of fluids. Utilizing an adjusted 3-D printer, they infused strings of water into silicone oil — chiseling tubes made of one fluid in another fluid.

They imagine their everything fluid material could be utilized to develop fluid hardware that power adaptable, stretchable gadgets. The researchers likewise predict synthetically tuning the tubes and streaming atoms through them, prompting better approaches to isolate particles or decisively convey nanoscale building squares to under-development mixes.

The analysts have printed strings of water between 10 microns and 1 millimeter in width, and in an assortment of spiraling and fanning takes care of business to a few meters long. Furthermore, the material can fit in with its environment and over and again change shape.

Tom Russell, a visiting faculty scientist in Berkeley Lab’s Materials Sciences Division said, “It’s a new class of material that can reconfigure itself, and it has the potential to be customized into liquid reaction vessels for many uses, from chemical synthesis to ion transport to catalysis.”

The report on their research is published March 24 in the journal Advanced Materials. Other co-authors include Joe Forth, a postdoctoral researcher in the Materials Sciences Division, as well as other scientists from Berkeley Lab and several other institutions.

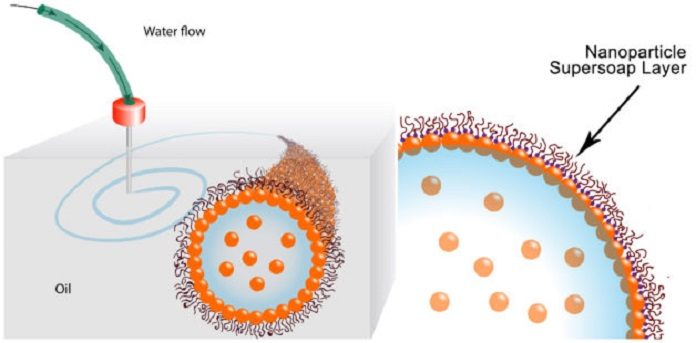

For the initial step, the researchers built up an approach to sheathe containers of water in a unique nanoparticle-inferred surfactant that secures the water. The surfactant, basically cleanser, keeps the tubes from separating into beads. Their surfactant is so great for its activity, the researchers call it a nanoparticle supersoap.

The supersoap was accomplished by scattering gold nanoparticles into water and polymer ligands into the oil. The gold nanoparticles and polymer ligands need to connect to each other, yet they additionally need to stay in their individual water and oil mediums. The ligands were produced with assistance from Brett Helms at the Molecular Foundry, a DOE Office of Science User Facility situated at Berkeley Lab.

Practically speaking, not long after the water is infused into the oil, many ligands in the oil append to individual nanoparticles in the water, framing a nanoparticle supersoap. These super soaps stick together and vitrify, similar to glass, which settles the interface amongst oil and water and secures the position of the fluid structure.

Russell said, “This stability means we can stretch water into a tube, and it remains a tube. Or we can shape water into an ellipsoid, and it remains an ellipsoid. We’ve used these nanoparticle super soaps to print tubes of water that last for several months.”

“We can squeeze liquid from a needle, and place threads of water anywhere we want in three dimensions. We can also ping the material with an external force, which momentarily breaks the supersoap’s stability and changes the shape of the water threads. The structures are endlessly reconfigurable.”