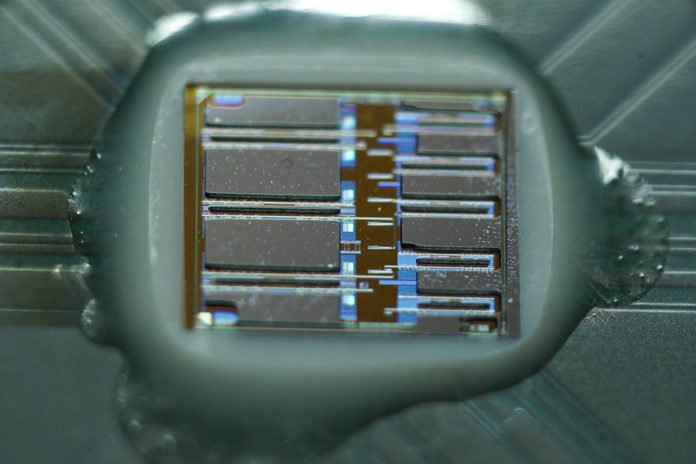

MIT spinout Ayar Labs in collaboration with a top silicon-chip manufacturer have developed novel optoelectronic chips, through which they expect to increase speed and reduce energy consumption in computing, starting with data centers.

As scientists reported, the chip can reduce energy usage by about 95 percent in chip-to-chip communications and increase bandwidth tenfold over their copper-based counterparts. The chips could also be used in supercomputers with efficiency similar to data centers.

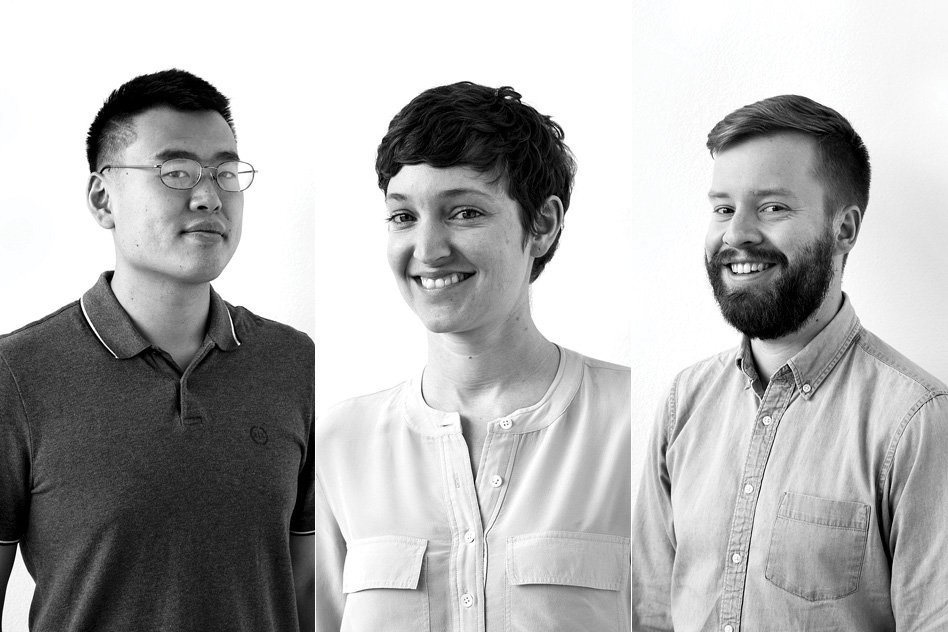

Wright-Gladstein, who co-founded Ayar with Chen Sun Ph.D. ’15 said, “Right now there’s a bandwidth bottleneck in big data centers. That’s an exciting application and the first place that really needs this technology.”

“The technology could also improve optics in various fields, from autonomous vehicles and medical devices to augmented reality. We’re excited about not just what this can do for data centers, but what new things this will enable in the future.”

Ayar’s core technology — now backed by more than 25 academic papers — is a decade in the making. The research collaboration began in the mid-2000s at MIT as part of the Defense Advanced Research Project Agency’s Photonically Optimized Embedded Microprocessors (POEM) project, led by Vladimir Stojanovic, now an associate professor of electrical engineering and computer science at the University of California at Berkeley, in collaboration with Rajeev Ram, an MIT professor of electrical engineering and principal investigator for the Physical Optics and Electronics group, and Milos Popovic, now an assistant professor of electrical and computer engineering at Boston University.

Scientists actually wanted to aid data transmission to keep up with Moore’s Law. Thus, the number of transistors on a chip may double every two years, but the amount of data we push across those copper pins hasn’t grown at the same rate.

Image courtesy of Ayar Labs

Computer chips send data between chips with different functions, such as logic chips and memory chips. With copper-based communications, however, the chips can’t send and receive enough data to take advantage of their increasing processing power. That’s caused a “bottleneck,” where chips must wait long durations to send and receive data.

The greater part the time in data centers, for example, circuits are sitting tight for information to travel every which way. It’s an enormous waste.

One solution is light. An optical wire can transmit numerous information motions on various wavelengths of light, while copper wires are constrained to one flag for each wire. Optical chips can, subsequently, transmit more data utilizing fundamentally less space. Also, photonics create next to no waste warmth.

Data going through copper wires produces a lot of waste warmth, which harms effectiveness in singular chips. This is an issue in server farms, where copper wires keep running inside and between servers.

At the time that the exploration gatherings of Ram, Stojanovic, and Popovic were dealing with the POEM venture, expansive organizations, for example, Intel and IBM were endeavoring to outline cheap, versatile optical chips. The cooperation — which at that point included Sun and Wade — adopted an alternate strategy: They coordinated optical parts onto silicon chips, which are created utilizing the customary CMOS semiconductor fabricating process that produces chips for pennies.

“That was radical thought at the time,” Wright-Gladstein says. “CMOS doesn’t loan itself well to optics, so industry veterans expected you’d need to roll out real improvements to inspire it to work.”

To avoid making changes to the CMOS process, the researchers focused on a new class of miniaturized optical components, including photodetectors, light modulators, waveguides, and optical filters that encode data on different wavelengths of light, and then transmit and decode it. They essentially “hacked” the traditional method for silicon chip design, using layers intended for electronics to build optical devices, and enabling chip designs to include optics more tightly configured than ever inside a chip’s structure.

Behind the scenes, Wright-Gladstein was already thinking about commercialization. The year before the publication, she had enrolled in the MIT Sloan School of Management, specifically to meet researchers tackling clean energy. Taking 15.366 (Energy Ventures), which focuses on commercializing MIT clean technologies, she was chosen to select the technologies to bring into the classroom. “That was the perfect excuse to meet every researcher doing energy-related research,” Wright-Gladstein says.

From the vast pool of 300 labs, she came across Ram’s optoelectronic chips — which “blew me away,” she says. The energy industry was focused on equipment innovations to save energy in data centers. “But there wasn’t much focus on reducing energy through computing itself,” Wright-Gladstein says. “It seemed like a great way to make an impact.”

Wright-Gladstein formed a team in class to create a business plan and pitch deck. She also collaborated frequently with Sun and Wade in speaking with potential industry clients. When the MIT Clean Energy Prize rolled around, the three students entered the technology under the name, OptiBit — and won both grand prizes for $275,000, solidifying their decision to launch a startup.

“Having funds early on to pay ourselves low salaries and having a little cushion before raising venture capital funds really persuaded us all to take the plunge,” Wright-Gladstein says.

Setting up shop in San Francisco, the startup proceeded with innovative work, expanding the correspondence information rates of the innovation. A year ago, GlobalFoundries appreciated these consistent developments and hit an organization with the startup, which incorporated some undisclosed financing. This year, Ayar’s first models should achieve U.S. server farms, with an arranged 2019 business discharge.

Tackling the chip input-yield issue is only the begin. Ayar is additionally amped up for what its new innovation implies for the field of optics, Wright-Gladstein says. Optical sensors, for example, are utilized as a part of self-driving or semiautonomous vehicles and costly medicinal hardware. Bringing down assembling costs, while expanding the calculation control, of optoelectronic chips could make those advances significantly less costly and more open.