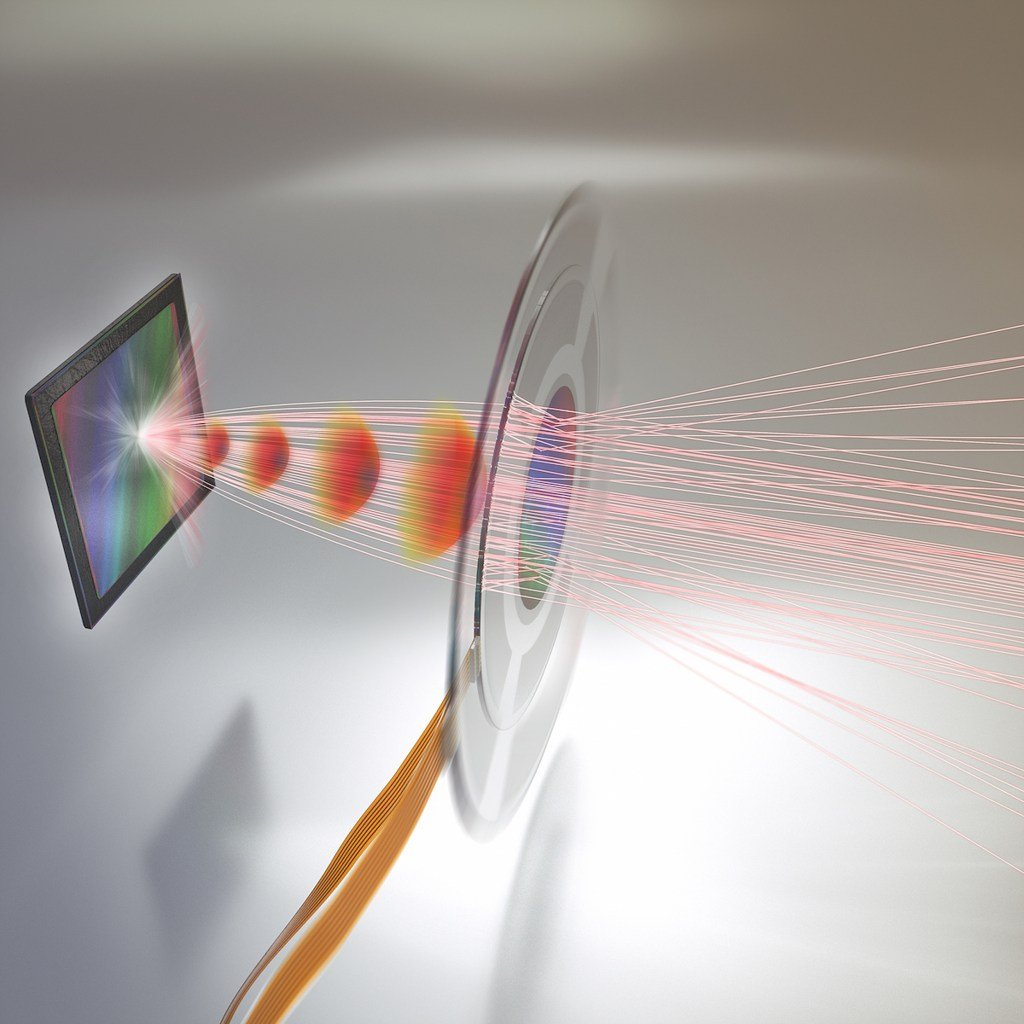

Getting inspired by the human eye, Harvard scientists have developed an adaptive metalens, an essentially flat artificial eye that can be monitored electronically. The most interesting specification of this metalens is that it controls three of the major contributors to blurry images: focus, astigmatism, and image shift.

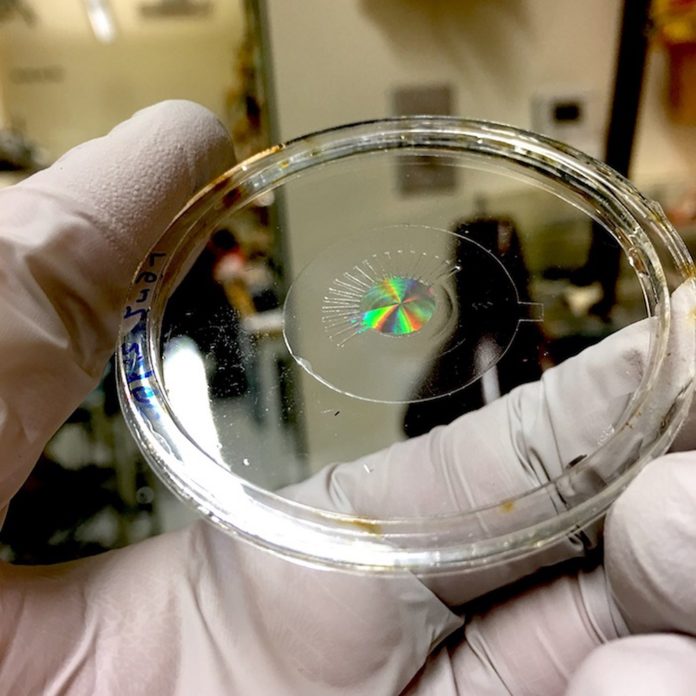

Scientists primarily developed the metalens that mainly focuses on light and minimizes spherical aberrations through a dense pattern of nanostructures. As nanostructures are so small, the information density in each lens will be high. For example, If you go from a 100 micron-size lens to a centimeter-size lens, you will have increased the information required to describe the lens by 10,000.

Alan She, a SEAS graduate student at the Graduate School of Arts and Sciences said, “This research combines breakthroughs in artificial muscle technology with metalens technology to create a tunable metalens that can change its focus in real time, just like the human eye. We go one step further to build the capability of dynamically correcting for aberrations such as astigmatism and image shift, which the human eye cannot naturally do.”

Federico Capasso, senior author of the paper said, “This demonstrates the feasibility of embedded optical zoom and autofocus for a wide range of applications, including cell phone cameras, eyeglasses, and virtual and augmented reality hardware. It also shows the possibility of future optical microscopes, which operate fully electronically and can correct many aberrations simultaneously.”

Whenever scientists tried to scale up the lens, the file size of the design alone would balloon up to gigabytes or even terabytes. Thus, they created a new algorithm in order to shrivel the file size to make the metalens perfect with the innovation right now used to create integrated circuits.

Scientists described the design and fabrication of metalenses of up to centimeters or more in diameter in a paper recently published in Optics Express.

Later on, scientists adhere the large metalens to an artificial muscle without compromising its ability to focus light. In the human eye, the lens is surrounded by ciliary muscle, which stretches or compresses the lens, changing its shape to adjust its focal length.

Scientists then choose a thin, transparent dielectric elastomer with low loss — meaning light travels through the material with little scattering — to attach to the lens. For this, they primarily developed a platform to transfer and adhere the lens to the soft surface.

David Clarke, Extended Tarr Family Professor of Materials at SEAS said, “Elastomers are so different in almost every way from semiconductors that the challenge has been how to marry their attributes to create a novel multifunctional device and, especially, how to devise a manufacturing route.”

“As someone who worked on one of the first scanning electron microscopes (SEMs) in the mid-1960s, it is exhilarating to be a part of creating an optical microscope with the capabilities of an SEM, such as real-time aberration control.”

When the voltage is applied to elastomers, it stretches, the position of nanopillars on the surface of the lens shift. The researchers also demonstrated that the lens can simultaneously focus, control aberrations caused by astigmatisms, and perform image shift.

She said, “All-optical systems with multiple components — from cameras to microscopes and telescopes — have slight misalignments or mechanical stresses on their components, depending on the way they were built and their current environment, that will always cause small amounts of astigmatism and other aberrations, which could be corrected by an adaptive optical element.”

“Because the adaptive metalens is flat, you can correct those aberrations and integrate different optical capabilities onto a single plane of control.”

The research is published in Science Advances.