Peptide ligases which make peptide bonds are useful biochemical and biotechnological tools. They enable linkage-specific and site-specific protein modifications and precision biomanufacturing of biotherapeutics such as antibody-drug conjugates.

Scientists from Nanyang Technological University, Singapore (NTU Singapore) now have shown the secret to a peptide ligase’s ‘superglue’ property. By pinpointing how peptide ligases work to join proteins together, scientists found that the peptide ligase’s ‘superglue’ property lies in two specific regions of the enzyme. Due to those two regions, the peptide holds the potential to attach itself to other molecules, and to alter the rate at which it works.

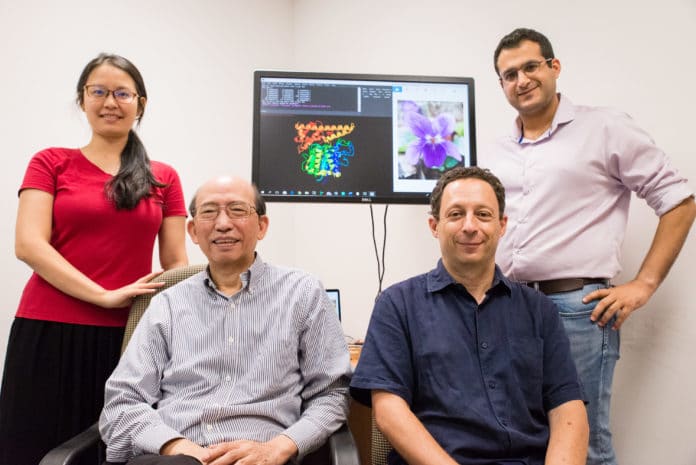

During the experiments, using their knowledge, scientists come up with a new lab-created peptide ligase-based on genetic information from the Chinese violet (Viola yedoensis), a medicinal plant with antibiotic and anti-inflammatory properties.

Dubbed as a recombinant peptide ligase, this lab-created peptide is expected to help in the development of drugs made from components taken from living organisms, as it overcomes the limitations of current methods, such as by-products or toxic molecules that may alter a drug’s function and efficacy.

Associate Professor Julien Lescar, who is also based in the NTU Institute of Structural Biology (NISB), said, “We’ve used what we have learned in nature to engineer a recombinant enzyme in the lab. It attaches itself to a specific protein, which then joins to another specific protein or molecule. This new way of doing things could underpin better diagnostic tests or anti-cancer drugs.”

Currently, during drug development, protein molecules are stitched together chemically. While this is efficient, the process leaves by-products that may alter the function of the end product.

Plant-derived peptide ligases have proven to be a more reliable protein ‘superglue’ than ligases derived from bacteria, or the use of chemicals to bind proteins together. Assoc Prof Lescar noted that plant-extracted enzymes may carry trace contaminants that could in turn trigger allergies, and the availability of the enzyme is dependent on successful growing and harvesting. In contrast, the new NTU-developed recombinant enzyme can be produced in labs in large quantities without any by-products.

Professor James Tam, who is also in the NISB, said, “In very simple terms, our work to create these ligases provides an improved platform for precision biomanufacturing of drugs, diagnostics, and biomaterials.”

Scientists examined the genetic information of enzymes extracted from the Chinese violet (Viola yedoensis) and the Canada violet (Viola canadensis). They then created five recombinant enzyme samples by inserting the enzymes’ genes into an insect cell culture. Of the five samples, three are peptide ligases. The other two are proteases, which are enzymes that cleave protein molecules into smaller peptide chains.

The team recently received funding from NTUitive, NTU’s innovation, and enterprise company, and is now working to develop the recombinant enzyme into a product. The product will be eventually sold at Epitoire, a start-up founded by Assoc Prof Lescar. The start-up sells DNA, RNA and protein reagents for academics and researchers who wish to do protein modification.

The team is also partnering both local and overseas medical schools and health institutions to use this recombinant enzyme in diagnostic imaging, such as brain tumor imaging during surgery.

A patent has been filed for the creation of the recombinant enzyme, as well as the mechanism that converts a protease into a ligase.

The study is reported in the journal PNAs.