Nanoindentation is a popular experimental technique for examining various small-scale mechanical properties of bulk materials and thin films. An Indian researcher has created a novel method that can be used to analyze the nanomechanical properties of materials at very tiny sizes with high precision and accuracy.

Using this new method, it is possible to test the mechanical strength of extremely small volumes of materials in a broad range of fields, including medicine, space, and aerospace. The method has been widely used to measure the strength of semiconductors devices and structural materials, permeating every aspect of our everyday lives via electronic devices. The technique has been used for various purposes, including diagnosing cancerous cells and determining how meteorites form in deep space.

Dr. Warren Oliver and Dr. John Pethica invented the nanoindentation technique in the 1980s, which was later proposed by Dr. Warren Oliver and Dr. George Pharr in their seminal work, which significantly impacted scientific research by enabling testing at nanoscales, typically 1/100th of the diameter of a human hair. It has been widely used in various sectors, including health and space.

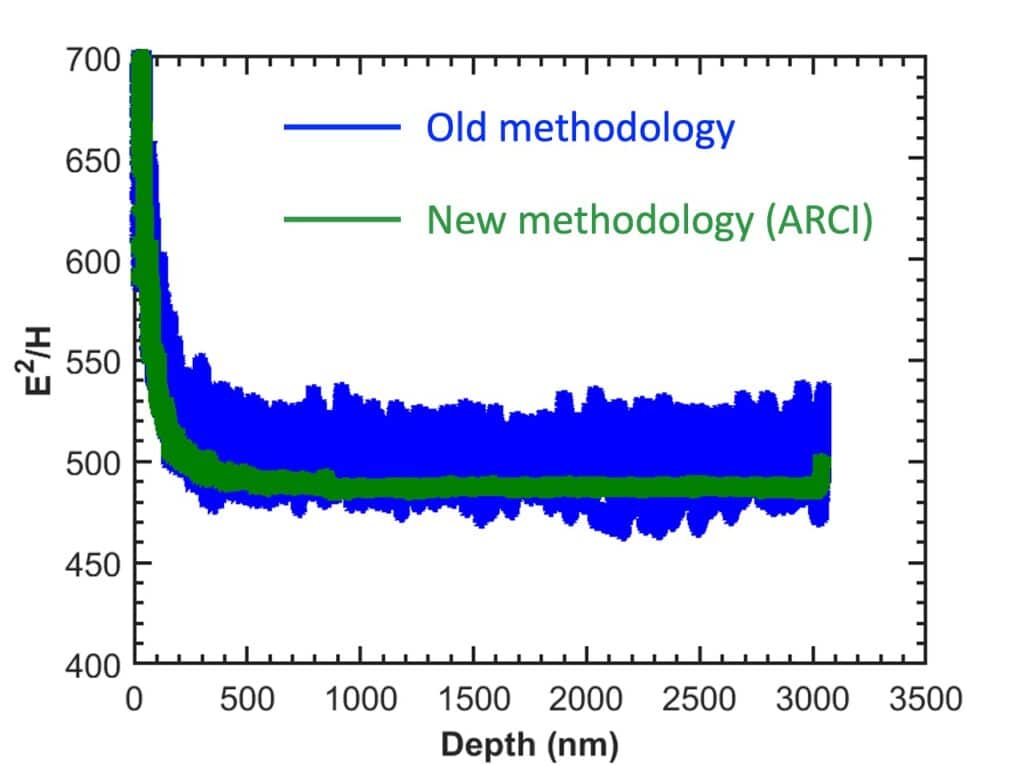

The new methodology required extensive modeling and simulation to understand how a material would react to an indentation test. After then, the process was tweaked to improve precision and accuracy. Extremely difficult trials were also employed to validate the modeling results. This is expected to impact a broad range of scientific studies on measuring the strength of materials at small scales by setting the tone for high precision and high accuracy nanoindentation measurements at far higher rates than previously possible.

The study will focus on the factors influencing plasticity error and repair method accuracy.

Journal Reference:

- P. Sudharshan Phani, G.M. Pharr, et al. An experimental assessment of methods for mitigating plasticity error during nanoindentation with continuous stiffness measurement. Materials & Design. DOI: 10.1016/j.matdes.2020.108924