Inspired by diving bell spiders and rafts of fire ants, scientists at the University of Rochester have created a metallic structure that does not sink in water, no matter how much you force into water.

Scientists have previously developed a groundbreaking technique that they developed for using femtosecond bursts of lasers to ‘etch’ the surfaces of metals with intricate micro- and nanoscale patterns. The technique helps make the surfaces superhydrophobic, or water repellent. However, after being immersed for a long time, the surfaces start losing their hydrophobic properties.

The diving bell spiders and fire ants can survive under or on the surface of the water for a long time. How? By trapping air in an encased area, the spiders, for instance, create a dome-shaped underwater web—a so-called diving bell—that they load up with air carried from the surface between their superhydrophobic legs and stomach abdomens. Similarly, fire ants can form a raft by trapping air among their superhydrophobic bodies.

Chunlei Guo, professor of optics and physics, said, “That was a fascinating inspiration. The key insight is that multifaceted superhydrophobic (SH) surfaces can trap a large air volume, which points towards the possibility of using SH surfaces to create buoyant devices.”

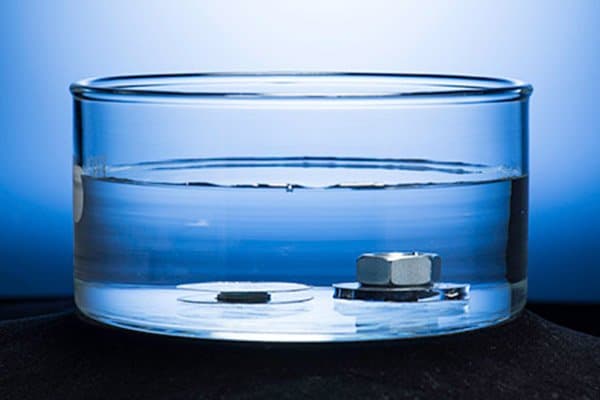

This new structure consists of the treated surfaces on two parallel aluminum plates facing inwards-enclosed and free from external wear and abrasion. The surfaces are separated by just the right distance to trap and hold enough air to keep the structure floating—in essence, making a waterproof compartment. The superhydrophobic surfaces will prevent water from entering the compartment in any event when the structure is compelled to submerge in water.

During experiments, scientists forcefully tried to submerge the material for two months. But, the structure denied immersing and bounced back to the surface after the load was released. What’s more, it also retained this ability even after being punctured several times.

When scientists first demonstrated the etching technique, it took an hour to pattern a one-inch-by-one-inch area of the surface. Now, by using lasers seven times as powerful, and faster scanning, the lab has speeded up the process, making it more feasible for scaling up for commercial applications.

Scientists noted, “The discovery could lead to manufacturing an unsinkable ship and also electronic monitoring devices that can survive in the long term in the ocean.”

Scientists described the structure in ACS Applied Materials and Interfaces.