Developed by MIT scientists, a new system can potentially provide a low-cost source of drinking water for parched cities around the world. It could save a substantial fraction of that lost water — and could even become a significant source of clean, safe drinking water for coastal cities where seawater is used to cool local power plants.

The system is originally the basis for a startup company called Infinite Cooling. Scientists actually wanted to improve the effectiveness of haze gathering systems that are utilized as a part of numerous water-scarce coastal regions as a source of clean drinking water. Those systems, which for the most part comprise or some likeness thereof of plastic or metal work hung vertically in the way of fogbanks that consistently come in from the sea, are extremely wasteful, catching just around 1 to 3 percent of the water droplets that go through them.

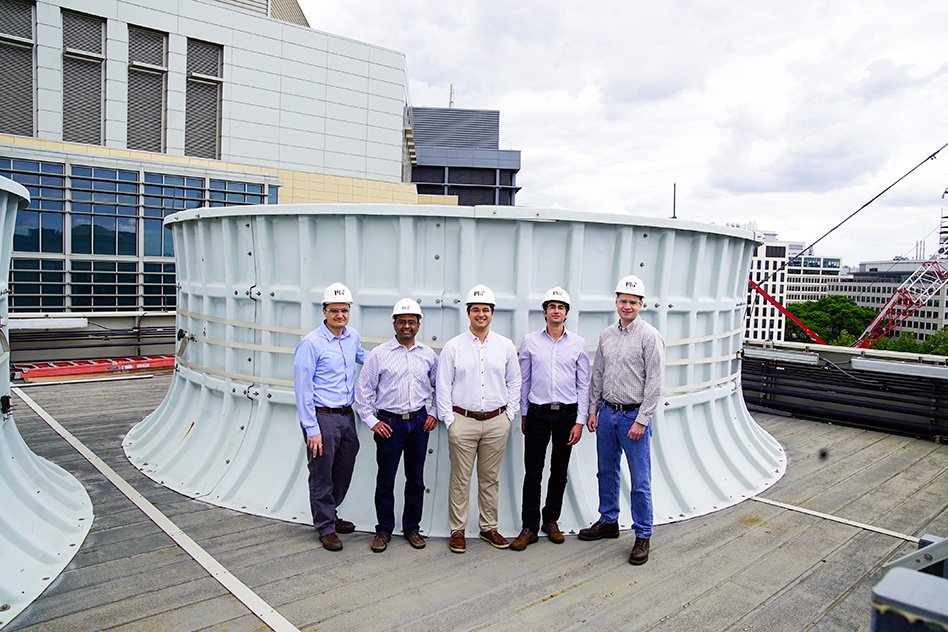

Image: Melanie Gonick/MIT

The reason for the inefficiency of existing systems became apparent in the team’s detailed lab experiments. This system can thus capture a much larger fraction of the droplets passing through. As such, it could dramatically improve the efficiency of fog-catching systems, and at a surprisingly low cost. The equipment is simple, and the amount of power required is minimal.

The principle behind the new concept is deceptively simple: When the air that’s rich in fog is zapped with a beam of electrically charged particles, known as ions, water droplets become electrically charged and thus can be drawn toward a mesh of wires, similar to a window screen, placed in their path. The droplets then collect on that mesh, drain down into a collecting pan, and can be reused in the power plant or sent to a city’s water supply system.

Next, the group concentrated on catching water from the tufts of power plant cooling towers. There, the water vapor stream is substantially more concentrated than any naturally occurring fog, and that makes the system considerably more proficient. Also, since catching evaporated water is in itself a distillation procedure, the water caught is pure, regardless of whether the cooling water is salty or contaminated.

Image: Christine Daniloff/MIT

Associate professor of mechanical engineering Kripa Varanasi said, “It’s distilled water, which is of higher quality, that’s now just wasted. That’s what we’re trying to capture.” The water could be piped to a city’s drinking water system, or used in processes that require pure water, such as in a power plant’s boilers, as opposed to being used in its cooling system where water quality doesn’t matter much.”

“A typical 600-megawatt power plant could capture 150 million gallons of water a year, representing a value of millions of dollars. This represents about 20 to 30 percent of the water lost from cooling towers. With further refinements, the system may be able to capture even more of the output.”

According to scientists, the installation cost of such a conversion would be about one-third that of a building a new desalination plant, and its operating costs would be about 1/50. The payback time for installing such a system would be about two years. In addition, it would have essentially no environmental footprint, adding nothing to that of the original plant.

Varanasi said, “This can be a great solution to address the global water crisis. It could offset the need for about 70 percent of new desalination plant installations in the next decade.”

The system is described in a paper published today in the journal Science Advances, co-authored by Maher Damak PhD ’18 and associate professor of mechanical engineering Kripa Varanasi. Damak and Varanasi are among the co-founders of the startup.