Researchers at the University of Illinois have developed a new polymer manufacturing process that could reduce the cost, time and energy needed, compared with the current manufacturing process.

The discovery could pave the way to new polymerization process that uses 10 orders of magnitude less energy.

During aircraft assembly, the manufacturing process of any single part consumes almost 96,000 kilowatt-hours of energy and produce more than 80 tons of CO2. That is roughly the amount of electricity it takes to supply nine average homes for one year.

Aerospace engineering professor and lead author Scott White said, “This development marks what could be the first major advancement to the high-performance polymer and composite manufacturing industry in almost half a century.”

“The materials used to create aircraft and automobiles have excellent thermal and mechanical performance, but the fabrication process is costly in terms of time, energy and environmental impact. One of our goals is to decrease expense and increase production.”

“The airliner manufacturers use a curing oven that is about 60 feet in diameter and about 40 feet long – it is an incredibly massive structure filled with heating elements, fans, cooling pipes and all sorts of other complex machinery. The temperature is raised to about 350 degrees Fahrenheit in a series of very precise steps over a roughly 24-hour cycle. It is an incredibly energy-intensive process.”

Scientists proposed that they could control substance reactivity to manage the polymer-curing process. There is a lot of vitality put away in the gum’s synthetic bonds to fuel the procedure. Figuring out how to release this vitality at simply the correct rate – not too quick, but rather not very moderate – was vital to the revelation.

White noted, “By touching what is essentially a soldering iron to one corner of the polymer surface, we can start a cascading chemical-reaction wave that propagates throughout the material. Once triggered, the reaction uses enthalpy, or the internal energy of the polymerization reaction, to push the reaction forward and cure the material, rather than an external energy source.”

The group has shown that this response can create sheltered, amazing polymers in an all-around controlled research facility condition. They imagine the procedure obliging extensive scale creation because of its similarity with usually utilized manufacture systems like embellishment, engraving, 3-D printing and tar implantation.

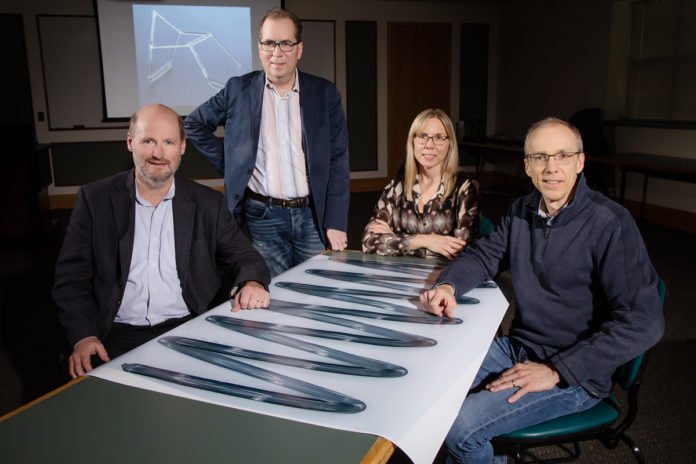

The team is part of the Beckman Institute for Advanced Science and Technology at the University of Illinois at Urbana-Champaign and includes White, chemistry professor and Beckman Institute director Jeffrey Moore, aerospace engineering professor and department head Philippe Geubelle, and materials science and engineering professor Nancy Sottos.

“You can save energy and time, but that does not matter if the quality of the final product is substandard,” Sottos said. “We can increase the speed of manufacturing by triggering the hardening reaction from more than one point, but that needs to be very carefully controlled. Otherwise, the meeting spot of the two reaction waves could form a thermal spike, causing imperfections that could degrade the material over time.”

The findings reported in Nature.