MIT engineers have recently bought a component of fun in microfluidics.

The field of microfluidics includes minute gadgets that correctly control liquids at submillimeter scales. Such gadgets normally appear as level, two-dimensional chips, carved with small channels and ports that are masterminded to perform different operations, for example, blending, arranging, pumping, and putting away liquids as they stream.

Courtesy of the researchers

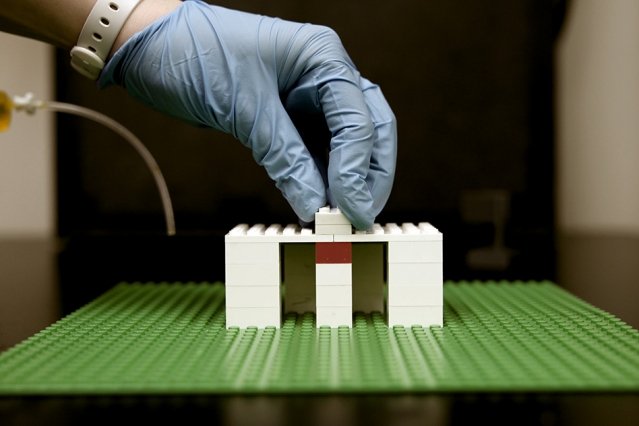

Presently the MIT group, looking past such lab-on-a-chip plans, has discovered an option microfluidics stage in “interlocking, infusion shaped squares” — or, as the vast majority of us know them, LEGO blocks.

Surely, LEGO blocks are made so reliably that regardless of where on the planet they are discovered, and two blocks are ensured to arrange and snap safely set up. Given this high level of accuracy and consistency, the MIT specialists picked LEGO blocks as the reason for another secluded microfluidic outline.

Courtesy of the researchers

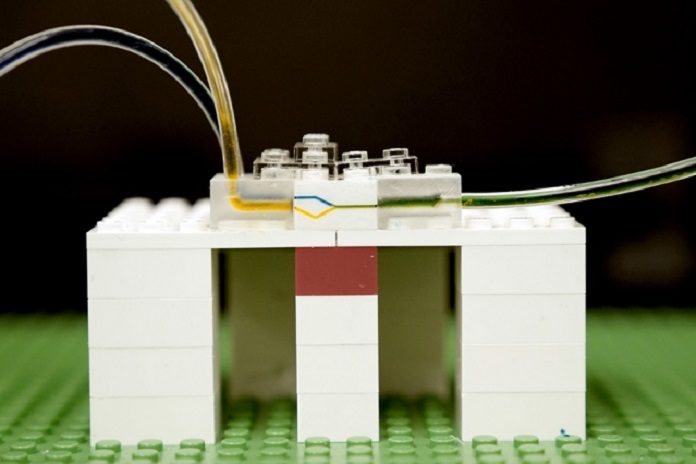

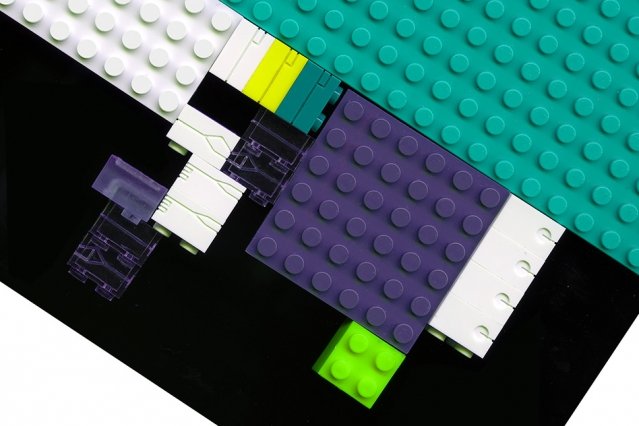

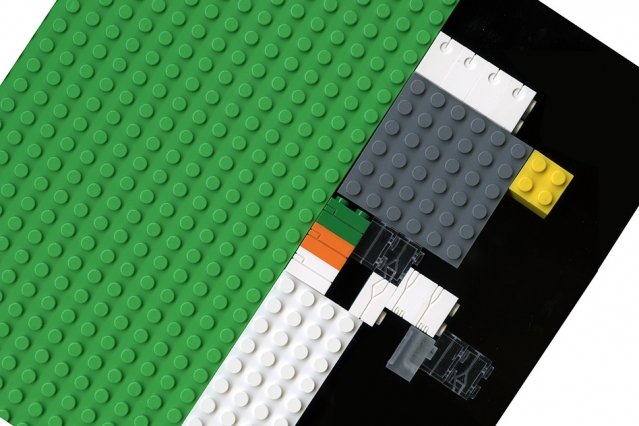

In a paper distributed in the diary Lab on a Chip, the group depicts micro milling little channels into LEGOs and situating the outlet of each “fluidic block” to fix up definitely with the delta of another block. The specialists at that point fixed the dividers of each adjusted block with a glue, empowering measured gadgets to be effortlessly amassed and reconfigured.

Every block can be composed with a specific example of channels to play out a particular errand. The analysts have so far designed blocks as liquid resistors and blenders and in addition bead generators. Their fluidic blocks can be snapped together or dismantled, to shape measured microfluidic gadgets that perform different organic operations, for example, arranging cells, blending liquids, and sifting through particles of intrigue.

Courtesy of the researchers

Anastasios John Hart, associate professor of mechanical engineering at MIT said, “LEGOs are fascinating examples of precision and modularity in everyday manufactured objects.”

Lead author Crystal Owens, a graduate student in MIT’s Department of Mechanical Engineering said, “You could then build a microfluidic system similarly to how you would build a LEGO castle — brick by brick. We hope in the future, others might use LEGO bricks to make a kit of microfluidic tools.”

Scientists at very first focused on new manufacturing processes, with applications ranging from nanomaterials to large-scale 3-D printing.

Courtesy of the researchers

Most microfluidic gadgets contain all the essential channels and ports to play out different operations on one chip. Owens and Hart searched for approaches to, generally, detonate this one-chip stage and make microfluidics secluded, appointing a solitary operation to a solitary module or unit. A scientist could then blend and match microfluidic modules to perform different mixes and arrangements of operations.

In casting around for ways to physically realize their modular design, scientists found the perfect template in LEGO bricks, which are about as long as a typical microfluidic chip.

Courtesy of the researchers

Hart said, “Because LEGOs are so inexpensive, widely accessible, and consistent in their size and repeatability of mounting, disassembly, and assembly, we asked whether LEGO bricks could be a way to create a toolkit of microfluidic or fluidic brick.”

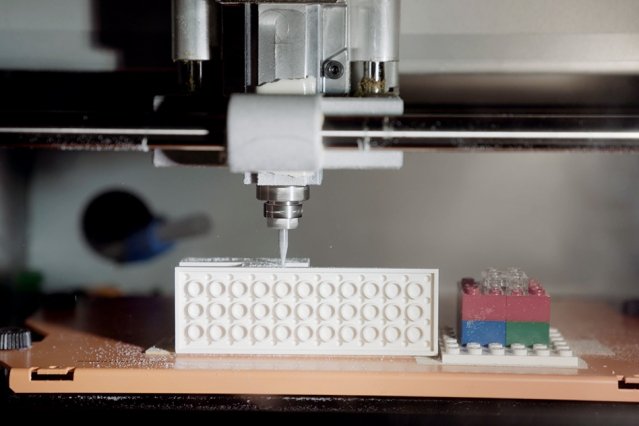

To answer this inquiry, the group acquired an arrangement of standard, off-the-rack LEGO blocks and attempted different approaches to bring microfluidic channels into every block. The best strategy ended up being micro-milling, a settled system generally used to bore to a great degree fine, submillimeter highlights into metals and different materials.

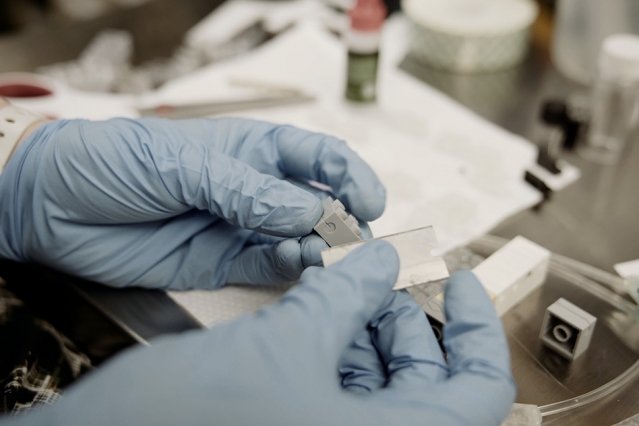

Owens utilized a work area micro mill to the first factory a straightforward, 500 far-reaching channel into the side mass of a standard LEGO block. She at that point taped a reasonable film over the divider to seal it and drew liquid through the block’s recently processed channel. She watched that the liquid effectively moved through the channel, showing the block worked as a stream resistor — a gadget that enables little measures of liquid to move through.

Utilizing this same method, she created a liquid blender by processing an even, Y-formed channel, and sending an alternate liquid through each arm of the Y. Where the two arms met, the liquids effectively blended. Owens additionally transformed a LEGO block into a drop generator by processing a T-formed example into its divider. As she pumped liquid through one end of the T, she found that a portion of the fluid dropped down through the center, framing a bead as it left the block.

To exhibit measured quality, Owens constructed a model onto a standard LEGO baseplate comprising of a few blocks, each intended to play out an alternate operation as liquid is pumped through. Notwithstanding making the liquid blender and bead generator, she likewise equipped a LEGO block with a light sensor, unequivocally situating the sensor to quantify light as liquid went through a channel at a similar area.

Owens said, “The hardest part of the project was figuring out how to connect the bricks together, without fluid leaking out. While LEGO bricks are designed to snap securely in place, there is nevertheless a small gap between bricks, measuring between 100 and 500 microns. To seal this gap, Owens fabricated a small O-ring around each inlet and outlet in a brick.”

“The O-ring fits into a small circle milled into the brick surface. It’s designed to stick out a certain amount, so when another brick is placed beside it, it compresses and creates a reliable fluid seal between the bricks. This works simply by placing one brick next to another. My goal was to make it straightforward to use.”

Owens said, “We’ve been experimenting with different coatings we could put on the surface to make LEGO bricks, as they are, compatible with different fluids. LEGO-like bricks could also be made out of other materials, such as polymers with high-temperature stability and chemical resistance.”

Hart said, “Our method provides an accessible platform for prototyping microfluidic devices. If the kind of device you want to make, and the materials you work with, are suitable for this kind of modular design, this is an easy way to build a microfluidic device for lab research.”