There is a strong requirement for diagnosis that treats age-related degenerative muscle and tendon diseases. A critical bottleneck in the disclosure and advancement of novel medications for skeletal muscle is the absence of productive and hearty useful in vitro tests for compound screening.

In a new study, scientists at Switzerland have developed a novel screening platform with automated production of 3D muscle- and tendon-like tissues using 3D bioprinting. The curiosity and significance of this new approach is the blend of the automated musculoskeletal tissue creation utilizing 3D bioprinting with another microwell plate addressing the particular tissue connection requirements. Along these lines, this screening stage speaks to a promising new device for musculoskeletal drug discovery and improvement.

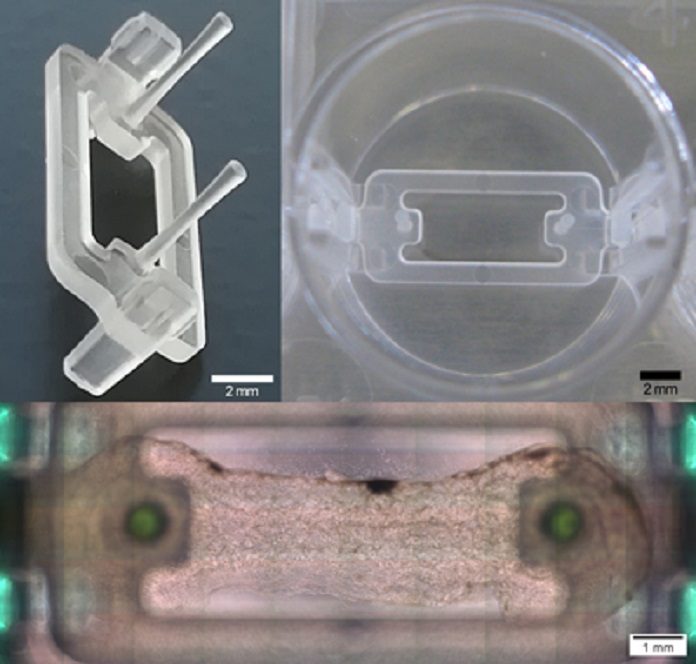

Muscle and tendon tissue models are fabricated by printing alternating layers of photo-polymerized gelatin-methacryloyl-based bioink and cell suspensions in a dumbbell shape onto a newly designed cell culture insert in 24-well plates containing two vertical posts. The cells show high viability after printing in culture and good tissue differentiation based on marker gene and protein expressions.

The usefulness of the muscle tissue models is demonstrated by calcium signaling of Fluo4-loaded cells and myofiber contractility prompted by electrical pulse stimulation. At last, the scientists effectively manufacture tendon muscle-tendon co-cultures by printing tenocytes around the posts of the cell culture embeds and myoblasts between the posts.

Scientists reported their findings in the Sage Journals.