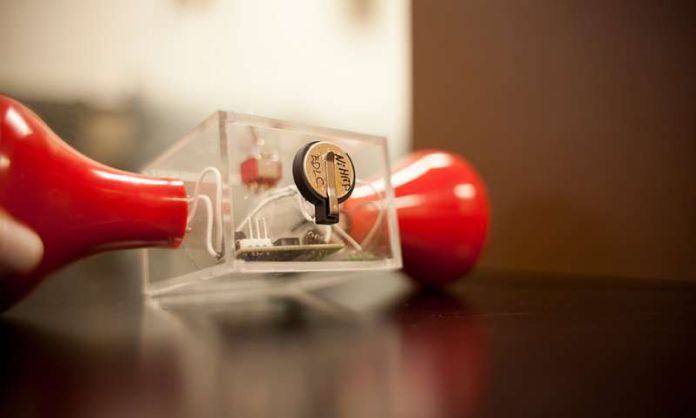

Scientists from MIT have developed new supercapacitor that does not use carbon. It could potentially produce more power than existing versions of this technology.

Generally, supercapacitor uses carbon material-nanotubes, graphene, activated carbon, all shapes and forms. They require high temperatures and harsh chemicals to produce. Although, supercapacitor becomes an interesting research part for scientists as it charged rapidly and deliver intense bursts of power.

Mircea Dinca said, “We’ve found an entirely new class of materials for supercapacitor.”

The key element for this new type of supercapacitor is metal-organic frameworks (MOF). The MOFs are extremely porous, sponge-like structures. These materials have an extraordinarily large surface area for their size. Also, they are much greater than the carbon materials. Generally, the performance of supercapacitor depends on their surface area. But MOFs have a major drawback for such applications: They are not very electrically conductive, which is also an essential property for a material used in a capacitor. The MOF exhibit another essential characteristic for such electrodes.It conducts ions very well.

Dinca says, “We want to these materials electrically conductive. Even though doing so “was thought to be extremely difficult, if not impossible.”

“All double-layer supercapacitors today are made from carbon. So this is the first noncarbon, electrical double-layer supercapacitor,” he added.

READ| Fast-charging everlasting Power from Graphene

Scientists produce this new material without optimizing characteristics. They match or exceed the performance of existing carbon-based versions in key parameters.

The material Ni3(hex imino triphenylene)2 used in these experiments was made under much less harsh conditions. (Carbon materials need very high temperatures above 800 degrees Celsius and strong reagent chemicals for pretreatment.)

The device has the ability to store relatively large amounts of power. Thus, it could play an important role in making renewable energy sources. They could provide grid-scale storage. For example, it matches usage times with generation time or used in electric vehicles and other applications.

After the 10,000 cycles experiment, the test showed that the device lost less than 10 percent of their performance.

Dinca said, “It is just the beginning. MOFs are a large class of materials that can be tuned to a great extent by varying their chemical structure. Work on optimizing their molecular configurations to provide the most desirable attributes for this specific application causes variations that could outperform any existing materials.”

The exciting thing about the material, it is completely tunable. MOF material has advantages in the simplicity and potentially low cost of manufacturing. Thus, the materials used to make it are more expensive than conventional carbon-based materials.

He said, “The key advantage of that is that this work shows only the tip of the iceberg. With carbons, we know pretty much everything, and the developments over the past years were modest and slow. But the MOF we used is one of the lowest-surface-area MOF. Some of these materials can reach up to three times more than carbons. The capacity would then be astonishingly high, probably close to that of batteries, but with the power performance supercapacitor.”