Solid-state lithium-sulfur batteries hold great potential as a superior alternative to current lithium-ion batteries. They consist of a solid electrolyte, a lithium metal anode, and a sulfur cathode, offering increased energy density and lower costs.

These batteries could double the range of electric vehicles without increasing the battery pack’s weight, and their use of easily sourced materials makes them an economically viable and environmentally friendlier choice.

However, the challenges associated with sulfur cathodes have hindered the development of lithium-sulfur solid-state batteries. Sulfur is a poor electron conductor, and sulfur cathodes tend to expand and contract during charging and discharging, leading to structural damage and decreased contact with the solid electrolyte. These factors decrease the cathode’s ability to transfer charge, ultimately compromising the solid-state battery‘s overall performance and longevity.

Now, a team led by engineers at the University of California, San Diego, has developed a new cathode material for solid-state lithium-sulfur batteries that is electrically conductive and structurally healable.

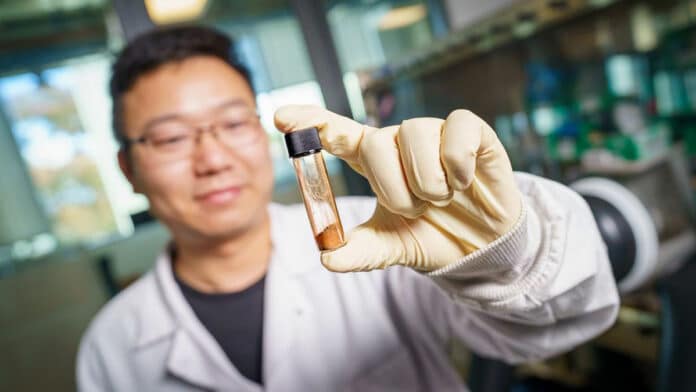

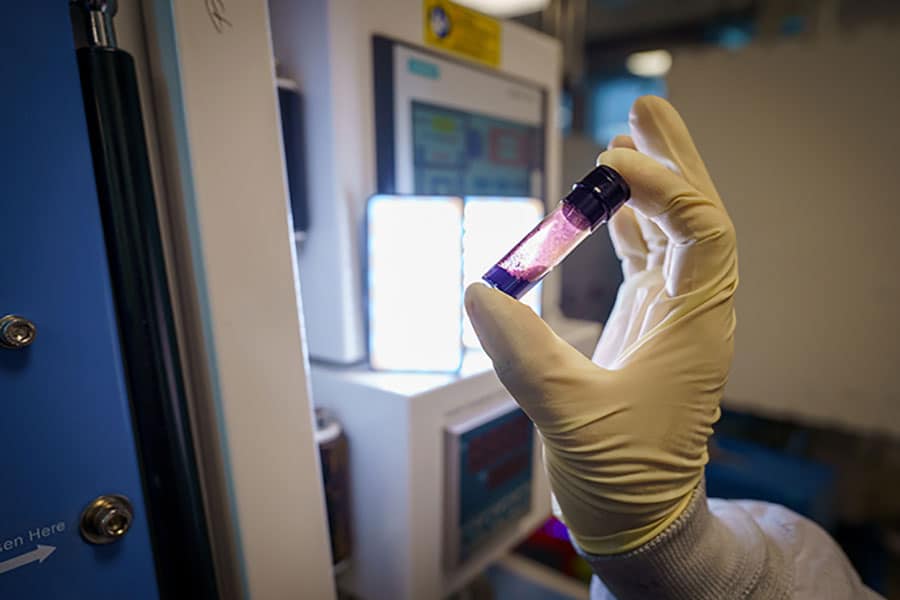

The new cathode material is a crystal composed of sulfur and iodine. By inserting iodine molecules into the crystalline sulfur structure, the researchers drastically increased the cathode material’s electrical conductivity by 11 orders of magnitude, making it 100 billion times more conductive than crystals made of sulfur alone.

“We are very excited about the discovery of this new material,” said study co-senior author Ping Liu, a professor of nanoengineering and director of the Sustainable Power and Energy Center at UC San Diego. “The drastic increase in electrical conductivity in sulfur is a surprise and scientifically very interesting.”

The new crystal material has a low melting point of only 65 degrees Celsius (149 degrees Fahrenheit), which is lower than the temperature of a hot cup of coffee. That means the battery’s cathode can be easily re-melted after the charging process to fix any damaged interfaces caused by cycling.

It’s an essential feature to combat the cumulative damage that occurs at the solid-solid interface between the electrolyte and cathode during repeated charging and discharging.

“This sulfur-iodide cathode presents a unique concept for managing some of the main impediments to commercialization of Li-S batteries,” said study co-senior author Shyue Ping Ong, a professor of nanoengineering at the UC San Diego Jacobs School of Engineering. “Iodine disrupts the intermolecular bonds holding sulfur molecules together by just the right amount to lower its melting point to the Goldilocks zone – above room temperature yet low enough for the cathode to be periodically re-healed via melting.”

“The low melting point of our new cathode material makes repairing the interfaces possible, a long sought-after solution for these batteries,” said study co-first author Jianbin Zhou, a former nanoengineering postdoctoral researcher from Liu’s research group. “This new material is an enabling solution for future high energy density solid-state batteries“.

Researchers constructed a test battery and subjected it to repeated charge and discharge cycles to validate the effectiveness of the new cathode material. According to their findings, the test battery remained stable for over 400 cycles while still retaining 87% of its capacity. The team will continue to advance the technology by improving cell engineering designs and scaling up the cell format.

“This discovery has the potential to solve one of the biggest challenges to the introduction of solid-state lithium-sulfur batteries by dramatically increasing the useful life of a battery,” said study co-author Christopher Brooks, chief scientist at Honda Research Institute USA, Inc. “The ability for a battery to self-heal simply by raising the temperature could significantly extend the total battery life cycle, creating a potential pathway toward real-world application of solid-state batteries.”

Journal reference:

- Jianbin Zhou, Manas Likhit Holekevi Chandrappa, Sha Tan, Shen Wang, Chaoshan Wu, Howie Nguyen, Canhui Wang, Haodong Liu, Sicen Yu, Quin R. S. Miller, Gayea Hyun, John Holoubek, Junghwa Hong, Yuxuan Xiao, Charles Soulen, Zheng Fan, Eric E. Fullerton, Christopher J. Brooks, Chao Wang, Raphaële J. Clément, Yan Yao, Enyuan Hu, Shyue Ping Ong & Ping Liu. Healable and conductive sulfur iodide for solid-state Li–S batteries. Nature, 2024; DOI: 10.1038/s41586-024-07101-z