As I said you earlier through my article ‘New Approach Makes 3D Printing Technique More Accessible‘, scientists are trying to expand 3D printing technology day by day. Computer Science Professors Michael Jones and Kevin Seppi from Brigham Young University had developed this technology. They just made an approach to make 3D printing more accessible. They removed the amount of skill required to design an object for 3D printing.

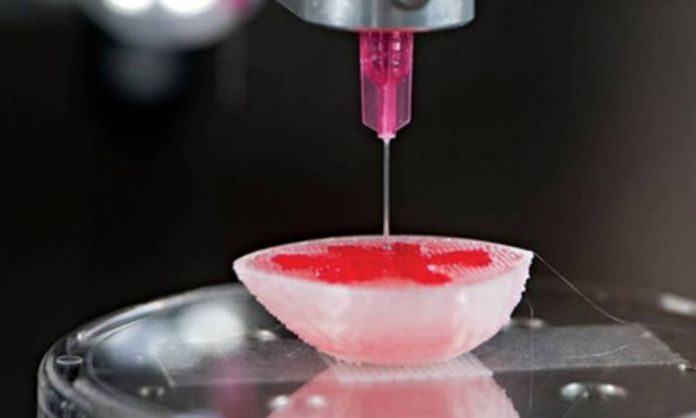

Scientists at the University of Bristol have developed a new kind of bio-ink for 3D printing. The bio-ink is a substance made up of living cells that can be printed into a specific shape. This new kind of bio- ink contain with stem cell allows for bioprinting, 3D printing of living tissue.

It consists of two different polymer components. First one is natural polymer drawn out from seaweed. The second polymer is a sacrificial synthetic polymer which is used in medical industry. Both polymers have a different role in this technology. The seaweed polymer supplies structural support when the cell nutrients are introduced. And the synthetic polymer causes the bio-ink to change from a liquid into solid when the temperature is increased.

Dr. Adam Perriman, from the School of Cellular and Molecular Medicine and lead researcher, said, “It was an extremely tough challenge to design this new kind of bio- ink. All you require a printable material which is strong enough to maintain shape while immersing in nutrients. This material should not harmful for the cells. We managed to do this, but there was a lot of trial and error before we cracked the final formation.”

This special bio-ink formation was ejected from a retrofitted benchtop 3D printer in the form of liquid. This liquid transformed into a gel at 37°C. It permits for building up of complex living 3D structures.

The team was able to split up the stem cells into osteoblasts and chondrocytes. The osteoblast is a cell that hides the substance of bone. Chondrocytes are cells that hide the matrix of cartilage and become embedded in it. The splitting was done to construct 3D printed tissue structures over five weeks, including a full-size tracheal cartilage ring.

Dr. Perriman said: “The really surprising fact was when the cell nutrients were introduced, the synthetic polymer was completely expelled from the 3D structure. It departs only the stem cells and the natural seaweed polymer. This, in turn, created microscopic pores in the structure, which provided more effective nutrient access for the stem cells.”

This new technology could be especially used in knee and hip surgeries.

Paper:

‘3D Bioprinting Using a Templated Porous Bioink‘ by James P. K. Armstrong, Madeline Burke, Benjamin M. Carter, Sean A. Davis, and Adam W. Perriman in Advanced Healthcare Materials.