Scientists at the Center for Nanoscale Materials (CNM), a U.S. Department of Energy (DOE) Office of Science User Facility located at the DOE’s Argonne National Laboratory, have developed a new machine-learning algorithm that allows them characterizing 3D microstructures of materials in real-time. Within seconds, the algorithm tells the user the exact microstructure in all three dimensions.

As scientists noted, it helps detect faults and cracks. Also, it can potentially predict the lifetimes under different stresses and strains for all kinds of structural materials.

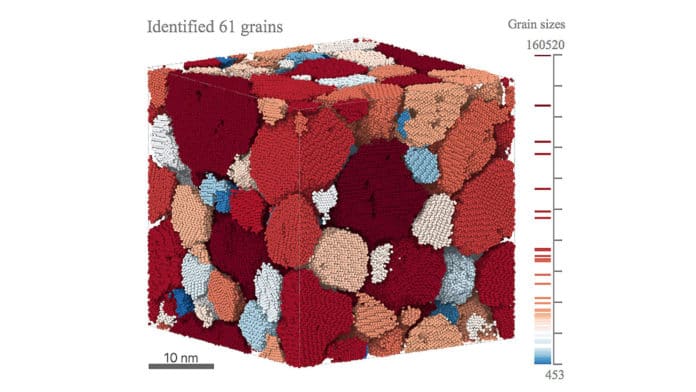

Henry Chan, CNM postdoctoral researcher and lead author of the study, said, “The beauty of our machine learning algorithm is that it uses an unsupervised algorithm to handle the boundary problem and produce highly accurate results with high efficiency. Coupled with down-sampling techniques, it only takes seconds to process large 3-D samples and obtain precise microstructural information that is robust and resilient to noise.”

Subramanian Sankaranarayanan, group leader of the CNM theory and modeling group, said, “For researchers using our tool, the main advantage is not just the impressive 3-D image generated but, more importantly, the detailed characterization data. They can even quantitatively and visually track the evolution of a microstructure as it changes in real-time.”

Scientists successfully tested the algorithm by comparison with data obtained from analyses of several different metals (aluminum, iron, silicon, and titanium) and soft materials (polymers and micelles).

Journal Reference:

- Machine learning-enabled autonomous microstructural characterization in 3-D samples. DOI: 10.1038/s41524-019-0267-z