Nacre, also known as the mother of pearl, is an organic-inorganic composite material produced by some mollusks as an inner shell layer. Also known as nature’s toughest material, the Nacre is the rainbow-sheened material that lines the insides of mussel and other mollusk shells.

Nacre’s combination of hardness and resilience has mystified scientists for more than 80 years. If humans could mimic it, it could lead to a new generation of ultra-strong synthetic materials for structures, surgical implants, and countless other applications.

Now, scientists for the first time revealed the mystery of nature’s toughest material.

Scientists have known that nacre is made of microscopic “bricks” of a mineral called aragonite, laced together with a “mortar” made of organic material. This blocks and-mortar clearly lends strength, yet nacre is far stronger than its materials recommend.

To crack the mystery, scientists used tiny piezo-electric micro-indenters to exert force on shells of Pinna nobilis, commonly known as the noble pen shell, while they were under an electron microscope. They watched what happened in real-time.

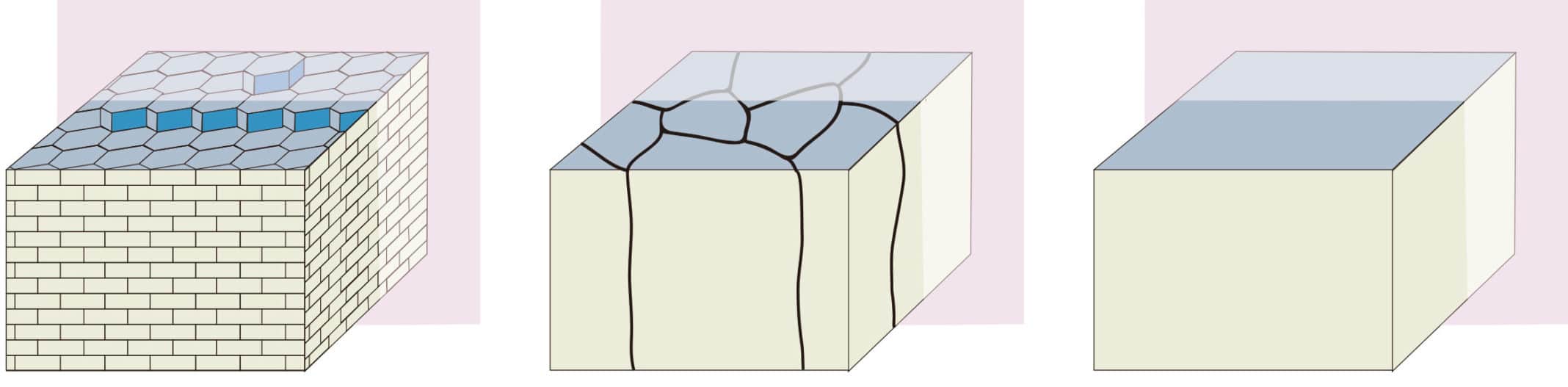

Scientists found that the bricks are actually multisided tablets just a few hundred nanometers in size. Ordinarily, these tablets remain s, arranged in layers and cushioned by a thin layer of organic “mortar.” But when stress is applied to the shells, the “mortar” squishes aside and the tablets lock together, shaping what is basically a strong surface. At the point when the power is expelled, the structure springs back, without losing any strength or resilience.

This resilience makes the nacre unique from even the most advanced human-designed materials. Nacre lost none of its resilience in repeated impacts at up to 80% of its yield strength. Even if the cracks form, the nacre confines the crack to a single layer rather than allowing it to spread, keeping the shell’s structure intact.

Robert Hovden, U-M assistant professor of materials science and engineering said, “It’s incredible that a mollusk, which is not the most intelligent creature, is fabricating so many structures across so many scales. It’s fabricating individual molecules of calcium carbonate, arranging them into nano-layered sheets that are glued together with organic material, all the way up to the structure of the shell, which combines nacre with several other materials.”

“Humans could use the mussel’s methods to create nano-engineered composite surfaces that could be dramatically lighter and stronger than those available today. Nature is handing us these highly optimized structures with millions of years of evolution behind them. We could never run enough computer simulations to come up with these—they’re just there for us to discover.”

Other co-authors of the study include Noah Schnitzer, Yuchi Cui and Amit Misra of U-M; Laura Otter and Dorrit Jacob of Macquarie University; Sébastien Montreuil and Frédéric Marin of Université de Bourgogne Franche-Comté; and Stephan Wolf of Friedrich-Alexander-University Erlangen-Nürnberg.

The study is published in the journal Nature Communications.