A new study by the University of Colorado Boulder revealed the secrets of fish fins. This study could help scientists create new designs for robotic surgical tools or even airplane wings.

Fish fins do not contain muscles. Still, they can change their shape with high precision and speed to produce large and complex hydrodynamic forces. These ‘flexo-morphing’ capabilities are rare in modern morphing and robotic materials.

Francois Barthelat, a senior author of the study, said, “If you look at a fin, you’ll see that it’s made of many stiff ‘rays.’ Each of those rays can be manipulated individually just like your fingers, but there are 20 or 30 of them in each fin.”

For the study, scientists used several approaches, including computer simulations and 3D-printed materials. These approaches help them get detailed insights into the biomechanics of these agile structures. They found that the secret behind the fish fins is their unique design.

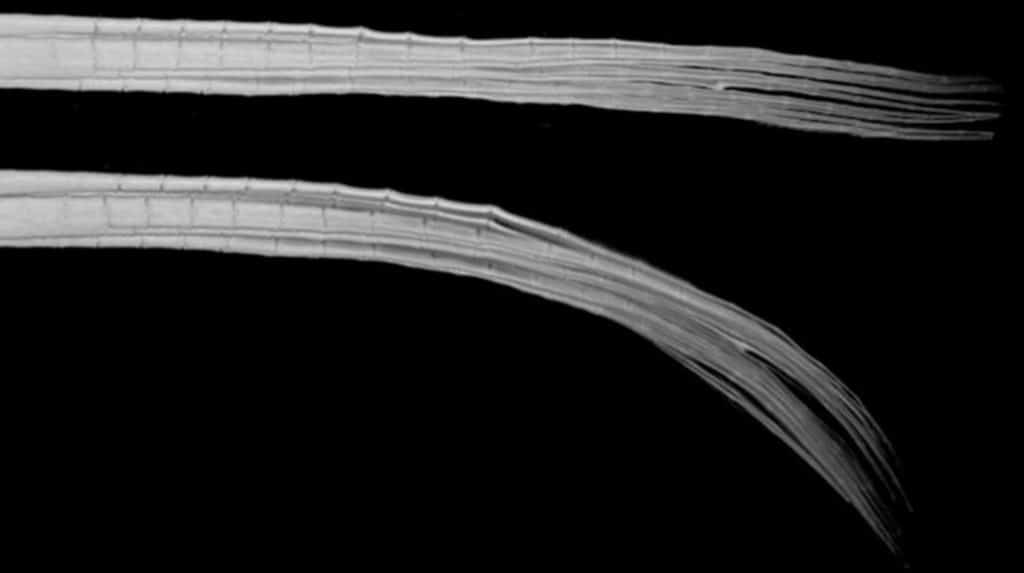

Each ray in a fin comprises multiple segments of a hard material that stack on top of much softer collagen, making them the perfect balance between bouncy and stiff.

Barthel said, “Fins may be just as useful. When it comes to engineering, materials that are both stiff and flexible are a hot commodity. Airplane designers, for example, have long been interested in developing wings that can morph on command, giving planes more ability to maneuver while still keeping them in the air.”

“Airplanes do this now, to some extent, when they drop their flaps. But that’s rigid. A wing made out of morphing materials, in contrast, could change its shape more radically and in a continuous manner, much like a bird.”

“The fins of run-of-the-mill goldfish has a layered structure, a bit like a bakery éclair: The spikes include two layers of stiff and mineralized materials called hemitrichs that surround an inner layer of spongy collagen. But those layers of hemitrichs aren’t solid. They’re divided into segments as if someone had cut up the éclair into bite-sized pieces.”

Using computer simulations, scientists examined the fin’s mechanical properties. They discovered that those segments could make all the difference.

Barthel said, “All of the segments, essentially, create these tiny hinges along the ray. When you try to compress or pull on those bony layers, they have very high stiffness. This is critical for the ray to resist and produce hydrodynamic forces that push on water. But if you try to bend individual bony layers, they’re very compliant, and that part is critical for the rays to deform easily from the base muscles.”

Using a 3D printer, scientists later tested the theory by creating model fish fins made from plastic—some with built-in hinges and some without. The idea panned out: The team found that the segmented design provided better stiffness and morphing capabilities combinations.

Barthel said, “We have only scratched the surface of the wide diversity of fins in the fish world. Flying fish, for example, deploy their fins to glide above the water, while mudskippers use their fins like legs to walk on land.”

“We like to pick up where the biologists and zoologists have left off, using our background in the mechanics of materials to further our understanding of the fantastic properties of the natural world.”

Journal Reference:

- Florent Hannard et al. Segmentations in fins enable large morphing amplitudes combined with high flexural stiffness for fish-inspired robotic materials. DOI: 10.1126/scirobotics.abf9710