Chitin is a type of dietary fiber that is found in mushrooms, fungi, and yeast, as well as in the exoskeleton of insects and the hard shells of shellfish.

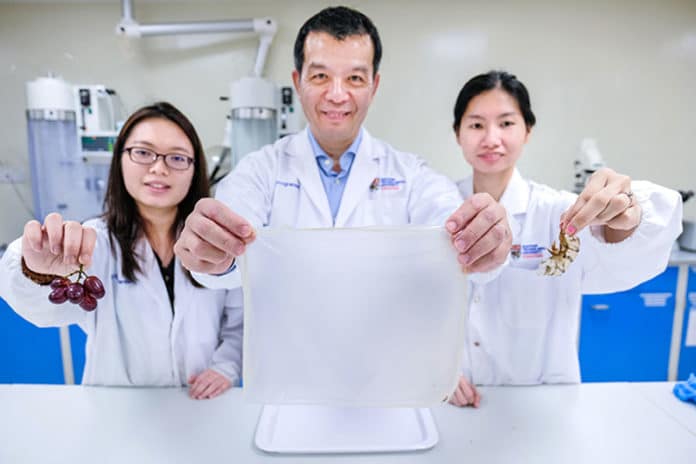

This time, scientists at Nanyang Technological University, Singapore (NTU Singapore), have come up with a new way to create chitin. They used two forms of food waste- prawn shells and discarded fruit – and fermenting them.

Existing methods include chemically extracting chitin from marine waste, which is costly, consumes large amounts of energy, and leads to chemical by-products that may be discharged in industrial wastewater. This newly developed method is more sustainable than those existing methods.

To come up with a new method, scientists tested ten sources of common fruit waste: white and red grape pomace, mango and apple peels, and pineapple cores, in various fermentation experiments. They found that sugar produced by fruit waste powered the fermentation process that breaks prawn shells down into chitin.

Later, by using the X-ray diffraction technique, scientists determined the atomic and molecular structure of the chitin created using the new method. They also quantified s level of purity using a ‘crystallinity index.’

The extracted crude chitin samples from prawn shells fermented using fruit waste gave a crystallinity index of 98.16 percent, which compared to commercial chitin samples with an index of 87.56 percent. The fermentation process using the sugar content from the fruit waste produced higher quality chitin than the commercial one.

Professor William Chen, Director of the Food Science and Technology program at NTU, said, “Our research has led to not only higher quality chitin but a more sustainable and environmentally-friendly process too. While the various types of fruit waste produced good results, the sugar from the pomace of red grapes had the best performance. This is also a cost-effective method for industry-scale operations, which could be of potential interest to wineries looking to reduce and upcycle their waste.”

“This research also echoes NTU’s translational research focus, which aims to develop sustainable innovations that benefit society and industry and create a greener future.”

Mr. Loo Yuen Meng, Managing Director of Integrated Aqua Singapore Pte. Ltd., who was not involved in the study, said, “The latest innovations developed by Prof William Chen from the Food Science and Technology program at NTU, is an excellent example of how the expertise from an institute of higher learning can be applied to improve the operational efficiency of the food industry while reducing food processing waste. Through a simple fermentation process, the high-value chitin and chitosan recovered from the prawn shells are environment-friendly, and the products can be re-connected back to the food industry.”

By leaving chitin to undergo further stages of fermentation, the NTU research team also found they could ferment it further into chitosan, which can be used as a growth enhancer in plant fertilizers, or as a controlled drug delivery system in pharmaceutical treatments.

More ways to use chitosan to enhance previous research innovations such as food packaging created using soybean residue or Okara are under exploration. Scientists believe that their study could pave the way towards the development of a more durable cellulose film with anti-microbial and anti-bacterial properties.

Journal Reference:

- Yun Nian Tan, Microbial extraction of chitin from seafood waste using sugars derived from fruit waste-stream. DOI: 10.1186/s13568-020-0954-7