Frothy bubbles in many industrial processes, such as in bioreactors that produce fuels or pharmaceuticals, can take up a lot of space. This limits most of the volume- available for making the product and sometimes gumming up pipes and valves or damaging living cells.

Now, MIT scientists have come up with a method to reduce foam buildup. The technique uses bubble-attracting sheets of specially textured mesh that make bubbles collapse as fast as they form.

Scientists primarily created a high-speed video with an intent to understand how bubbles react when they strike a surface. They found that the bubbles tend to bounce away like a rubber ball, bouncing several times before, in the end, staying set up, similarly as beads of liquid do when they hit a surface, only upside down.

Leonid Rapoport Ph.D. ’18 said, “To effectively capture the impacting bubble, we had to understand how the liquid film separating it from the surface drains. And we had to start at square one because there wasn’t even an established metric to measure how good a surface is at capturing impacting bubbles. Ultimately, we were able to understand the physics behind what causes a bubble to bounce away, and that understanding drove the design process.”

Scientists designed a flat device that has a set of carefully designed surface textures at a variety of size scales. The surface was tuned so that bubbles would adhere immediately without bobbing, and quickly spread out and dissipate to clear a path for the next bubble as opposed to amassing as foam.

Visiting student Theo Emmerich said, “The key to quickly capturing bubbles and controlling foam turned out to be a three-layered system with features of progressively finer sizes. These features help to trap a very thin layer of air along the surface of a material. This surface, known as a plastron, has similarities to the texture of some feathers on diving birds that help keep the animals dry underwater. In this case, the plastron helps to make the bubbles stick to the surface and dissipate.”

Professor of mechanical engineering Kripa Varanasi said, “The net effect is to reduce the time it takes for a bubble to stick to the surface by a hundredfold. In tests, the bouncing time was reduced from hundreds of milliseconds to just a few milliseconds.”

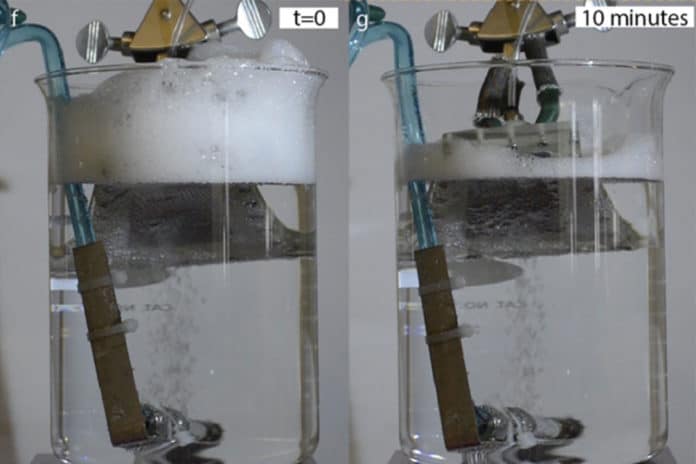

Scientists tested the idea using a device containing a bubble-capturing surface and inserted it into a beaker that had bubbles rising through it. They place that beaker next to an identical one containing foaming suds with a sheet of similar size yet without the finished material.

In the beaker with the bubble-capturing surface, the foam immediately scattered down to nothing, while a full layer of foam remained set up in the other container.

Varanasi said, “Such bubble-capturing surfaces could easily be retrofitted to many industrial processing facilities that currently rely on defoaming chemicals. He speculated that in the longer run, such a method might even be used as a way to capture methane seeping from melting permafrost as the world warms. This could both prevent some of that potent greenhouse gas from making it into the atmosphere, and at the same time, provide a source of fuel. At this point, that possibility is “pie in the sky’, but in principle, it could work.”

The new process is described in the journal Advanced Materials Interfaces.