Fuel cells may well replace batteries as the power source for electric cars. They consume hydrogen, a gas that could be delivered, for example, using surplus electricity from wind power plants. In any case, the platinum used in fuel cells is uncommon and incredibly costly, which has been a constraining component in applications.

In fuel cells, hydrogen reacts with oxygen to create water, producing power. Sophisticated catalysts at the electrodes are required to optimize this conversion. Platinum plays a central role in the oxygen-reduction reaction.

Scientists at the Technical University of Munich (TUM) have now optimized the size of the platinum particles to such a degree that the particles perform at levels twice as high as the best processes commercially available today.

How small can a cluster of platinum atoms be and still have a highly active catalytic effect?

Roland Fischer, Professor of Inorganic and Organometallic Chemistry, who led the study, said, “It turns out that there are certain optimum sizes for platinum stacks.”

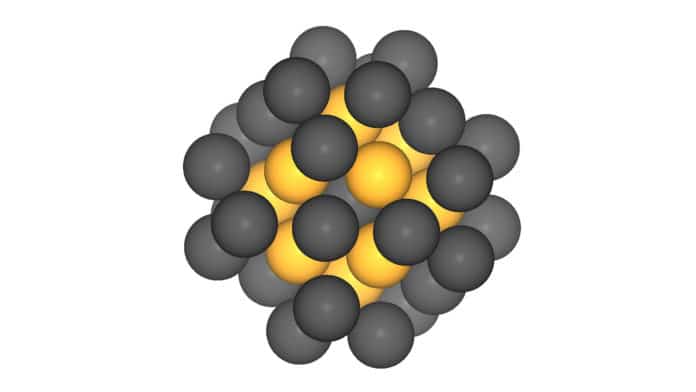

Aliaksandr Bandarenka, Physics of Energy Conversion and Storage and Alessio Gagliardi said, “Particles measuring about one nanometer and containing approximately 40 platinum atoms are ideal. Platinum catalysts of this order of size have a small volume but a large number of highly active spots, resulting in high mass activity.”

Combining theoretical capabilities in modeling, joint discussions, and physical and chemical knowledge gained from experiments eventually brought about a model indicating how catalysts can be structured with the ideal form, size, and size distribution of the components included.

Batyr Garlyyev, one of the lead authors of the study, said, “The experiment exactly confirmed the theoretical predictions. Our catalyst is twice as effective as the best conventional catalyst on the market, adding that this is still not adequate for commercial applications since the current 50 percent reduction of the amount of platinum would have to increase to 80 percent.”

In addition to spherical nanoparticles, the researchers hope for even higher catalytic activity from significantly more complex shapes. And the computer models established in the partnership are ideal for this kind of modeling. Nevertheless, more complex shapes require more complex synthesis methods. This will make computational and experimental studies more and more critical in the future.

The study is published in Angewandte Chemie.