A scientist at the Siberian Federal University (SFU) and Kirensky Institute of Physics Federal Research Center KSC SB RAS (IF) synthesized thin crystal ferromagnetic films and developed a technology for their shaping.

Scientists processed films can be used in electronic and spintronic chips.

They created these films that are hundreds to handfuls nanometers thick in the shape of iron silicides integrated on a silicon substrate.

Press silicides are mixes of iron and silicon that for the most part have ferromagnetic properties when subject to specific temperatures. There are likewise non-attractive iron silicides with one of a kind optic qualities that might be put to handy utilize.

Movies like this are utilized as dynamic parts in optic and photonic gadgets, and in vital electronic and spintronic chips. Thin ferromagnetic movies open a considerable measure of prospects for spintronics (a territory of science that accommodates the making of data stockpiling and preparing gadgets). Gadgets like this devour less electrical vitality and have higher working velocity contrasted with conventional electronic ones.

Anton Tarasov, a co-author of the article said, “We’ve broadened the application of this approach, extended it to new iron-silicon alloys, and showed that it works. We’ve also determined the speed of etching and developed a micro-device. The same methods may be used for the production of different structures in electronics, photonics, and other applications.”

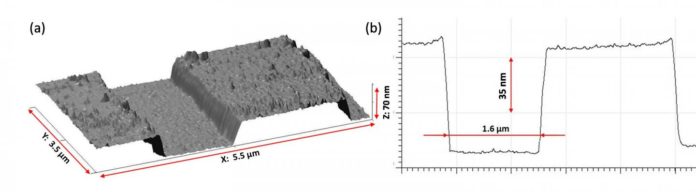

Scientists used films that are specifically shaped. Means, a template has to be applied to synthesized films, and they have to be cut according to it.

To do so, scientists use etching method so that they can either wet (chemical) or dry it(plasma, reactive-ion, or just ion). In the course of wet etching, a film is placed in liquid – an etching agent that dissolves the rest of it.

Before that scientists cover the films with “masks” using photolithography to set out required configuration. Such a mask protects the desired part of the film from solving. In dry etching, the same result is achieved using a gas that destroys the material physically or chemically.

They noted, “a big advantage of the new films is not only their electronic and magnetic properties but compatibility with the most popular technological semiconductors. It means, these films may be grown on bases made of silicon, germanium, and gallium arsenide.”

This will help the team obtain high-quality thin films with specific shapes and geometry in a simpler and more affordable way. Moreover, the obtained results increase the selection of materials that scientists may use to develop different devices.

Utilizing this innovation, one can make spintronic or photonic gadgets, since press silicides have properties pertinent in these regions of science. At the present time, we are developing new movies and concentrate the impacts that rely on their topology.