How much fuel does it take to catapult a rocket into space?

Each solid rocket booster held 1.1 million pounds of fuel. The external tank held 143,000 gallons of liquid oxygen (1,359,000 pounds) and 383,000 gallons of liquid hydrogen (226,000 pounds). The fuel weighed almost 20 times more than the Shuttle. At launch, the Shuttle, external tank, solid rocket boosters, and all the fuel combined had a total weight of 4.4 million pounds.

Now, scientists have paved the way towards a simple, fuel-efficient rocket engine that could enable cheaper, lighter spacecraft.

A new type of engine— called a rotating detonation engine — vows to make rockets more fuel-efficient as well as increasingly lightweight and less confounded to construct.

However, the engine is currently in the prototype stage, thus, it is unpredictable to be used in an actual rocket.

Scientists from the University of Washington have come up with a mathematical model that describes the working of the engine. The information can help scientists to improve these engines and make them more stable.

Lead author James Koch, a UW doctoral student in aeronautics and astronautics, said, “The rotating detonation engine field is still in its infancy. We have tons of data about these engines, but we don’t understand what is going on. I tried to recast our results by looking at pattern formations instead of asking an engineering question — such as how to get the highest performing engine — and then boom, it turned out that it works.”

“A rotating detonation engine takes a different approach to how it combusts propellant. It’s made of concentric cylinders. Propellant flows in the gap between the cylinders, and, after ignition, the rapid heat release forms a shock wave, a strong pulse of gas with significantly higher pressure and temperature that is moving faster than the speed of sound.”

“This combustion process is a detonation — an explosion — but behind this initial start-up phase, we see several stable combustion pulses form that continue to consume available propellant. This produces high pressure and temperature that drives exhaust out the back of the engine at high speeds, which can generate thrust.”

Unlike the conventional engine, this rotating detonation engine uses the shock wave naturally does everything without needing additional help from engine parts.

Koch said, “The combustion-driven shocks naturally compress the flow as they travel around the combustion chamber. The downside of that is that these detonations have a mind of their own. Once you detonate something, it just goes. It’s so violent.”

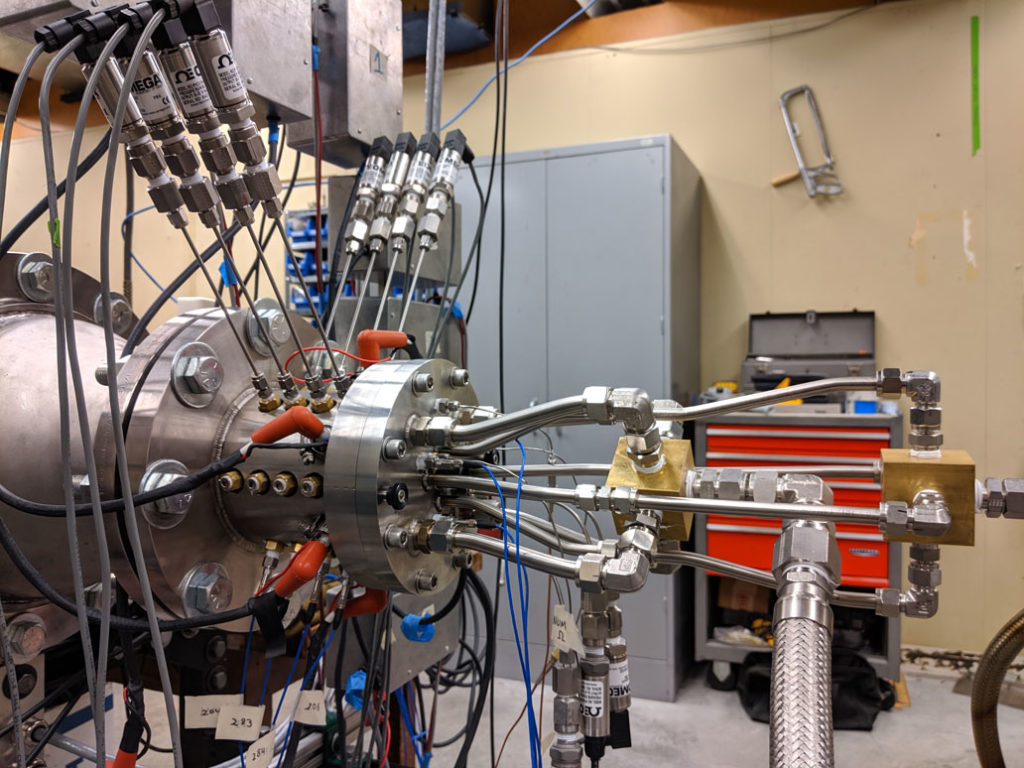

To describe the working of the engine, scientists primarily developed an experimental rotating detonation engine where they could control different parameters, such as the size of the gap between the cylinders. Then they recorded the combustion procedures with a fast camera. Each experiment took just 0.5 seconds to finish, yet the analysts recorded these trials at 240,000 frames for every second so they could perceive what was going on in slow motion.

Co-author J. Nathan Kutz, a UW professor of applied mathematics, said, “This is the only model in the literature currently capable of describing the diverse and complex dynamics of these rotating detonation engines that we observe in experiments.”

The model allowed the researchers to determine for the first time whether an engine of this type would be stable or unstable. It also allowed them to assess how well a specific engine was performing.

The team published these findings Jan. 10 in Physical Review E.