Scientists at the Purdue University have developed a new manufacturing process that holds the potential to improve the water repellency for some common products. The process is expected to be used in heat exchangers by removing condensed water drops, improving the heat transfer efficiency.

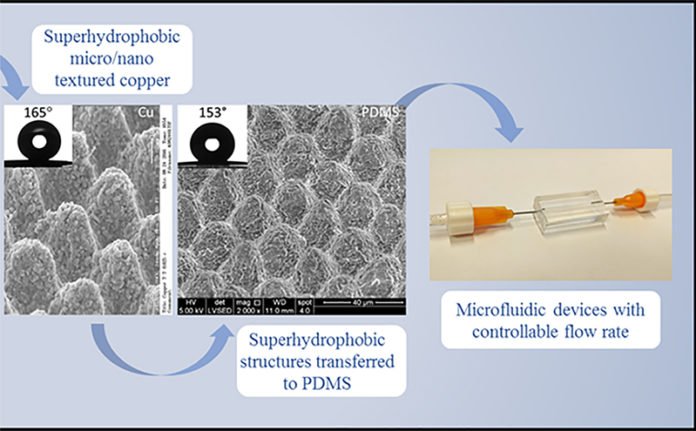

The process actually creates superhydrophobic microchannels on polymers, thus provides a quick and inexpensive fabrication technique to create microfluidic devices having channels with controllable flow rates. The channels are small that are made in such a way that water cannot stick to the surface or give little resistance in the flow.

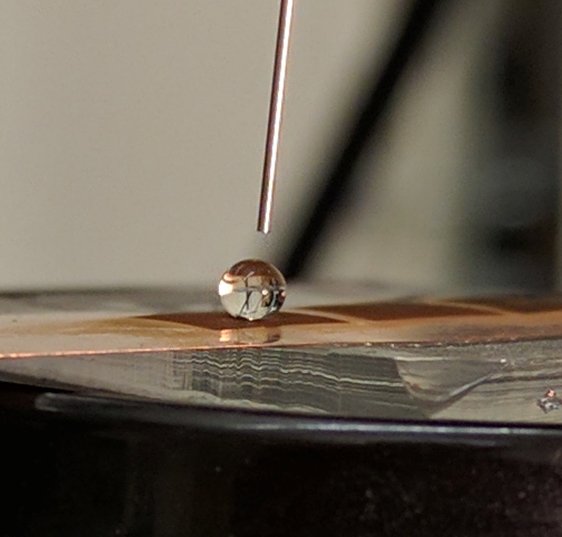

In order to create these surfaces, scientists primarily demonstrated patterns or features on a metal surface using an ultrafast laser. Then with the help of the process called transfer molding, they created the same pattern on the polymer.

Yung Shin, research head, said, “Our process is unique because it allows for the creation of these surface patterns or features on the inside of the polymer and not just the outside. We are essentially using these features to control flow rates without the need for expensive chemical treatments and coatings that can be washed away or wear off.”

“The technology has many potential applications, including medical equipment and sensors that use circulating fluid to detect abnormalities or unhealthy conditions in a patient. It could also be used for micro cooling systems for electronics, microfluidic devices, MEMS, self-cleaning surfaces, and micro-hydraulics systems in airplanes and automobiles. The technology could help create windshields that are better able to repel water and require less wiping.”

“Our technology can help with the continued miniaturization of electronic devices such as phones and computers. Our method of creating these superhydrophobic microchannels allows for smaller devices that perform at the same efficiency as much larger ones.”