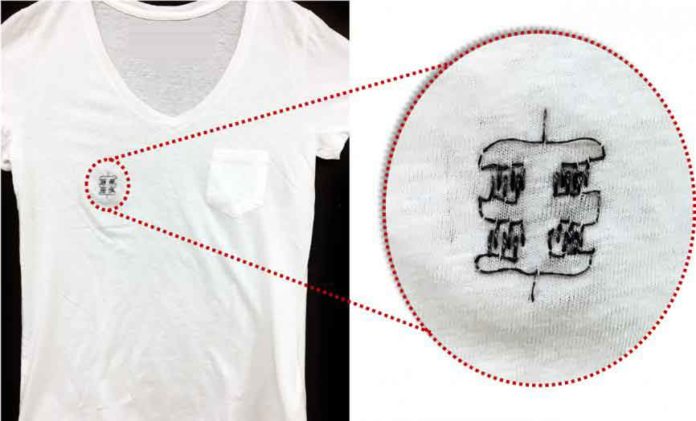

Scientists at the University of Massachusetts Amherst have developed a method for making a charge-storing system that is easily integrated into clothing for ’embroidering a charge-storing pattern onto any garment.’

The method uses a micro-supercapacitor and consolidates vapor-covered conductive threads with a polymer film, in addition to an uncommon sewing method to make a flexible mesh of adjusted anodes on a textile backing. The subsequent solid-state device has a high capacity to store charge for its size, and different attributes that enable it to control wearable biosensors.

Trisha L. Andrew, research led said, “Batteries or other kinds of charge storage are still the limiting components for most portable, wearable, ingestible or flexible technologies. The devices tend to be some combination of too large, too heavy and not flexible.”

“While researchers have remarkably miniaturized many different electronic circuit components until now the same could not be said for charge-storing devices. With this paper, we show that we can literally embroider a charge-storing pattern onto any garment using the vapor-coated threads that our lab makes. This opens the door for simply sewing circuits on self-powered smart garments.”

According to Andrew and postdoctoral researcher, Lushuai Zhang said, “supercapacitors are ideal candidates for wearable charge storage circuits because they have inherently higher power densities compared to batteries. But incorporating electrochemically active materials with high electrical conductivities and rapid ion transport into textiles is challenging.”

Through this study, scientists showed that their vapor covering process makes permeable directing polymer films on densely-twisted yarns, which can be effectively swelled with electrolyte particles and keep up high charge stockpiling limit per unit length when contrasted with earlier work with colored or expelled strands.

Andrew said, “Textile scientists have tended not to use vapor deposition because of technical difficulties and high costs, but more recently, research has shown that the technology can be scaled up and remain cost-effective.”

Scientists are now working with others at the UMass Amherst Institute for Applied Life Sciences’ Personalized Health Monitoring Center on incorporating the new embroidered charge-storage arrays with e-textile sensors and low-power microprocessors to build smart garments that can monitor a person’s gait and joint movements throughout a normal day.

Details appear online in ACS Applied Materials & Interfaces.