Materials researchers at Duke University have built up a technique to make half breed thin-film materials that would somehow be troublesome or difficult to make. The procedure could be the passage to new ages of sun based cells, light-transmitting diodes, and photodetectors.

Perovskites are a class of materials that—with the correct mix of components—have a crystalline structure that makes them especially appropriate for light-based applications. Their capacity to ingest light and exchange its vitality proficiently makes them a typical focus for analysts growing new kinds of sunlight based cells, for instance.

The most well-known perovskite utilized as a part of sun based vitality today, methylammonium lead iodide (MAPbI3), can change over light to vitality similarly and in addition the present best economically accessible sunlight based boards. What’s more, it can do it utilizing a small amount of the material—a bit 100 times more slender than an ordinary silicon-based sunlight based cell.

Methylammonium lead iodide is one of only a handful few perovskites that can be made utilizing standard industry creation systems, however, regardless it has issues with versatility and sturdiness. To really open the capability of perovskites, be that as it may, new assembling strategies are required on the grounds that the blend of natural and inorganic atoms in a complex crystalline structure can be hard to make. Natural components are especially sensitive, yet are basic to the half-breed material’s capacity to ingest and transmit light successfully.

David Mitzi, the Simon Family Professor of Mechanical Engineering and Materials Science said, “Methylammonium lead iodide has a very simple organic component, yet is a very high-performing light absorber. If we can find a new manufacturing approach that can build more complex molecular combinations, it will open new realms of chemistry for multifunctional materials.”

During the study, scientists demonstrate just such a manufacturing approach. The technique is called Resonant Infrared Matrix-Assisted Pulsed Laser Evaporation, or RIR-MAPLE for short, and was developed by Stiff-Roberts at Duke over the past decade.

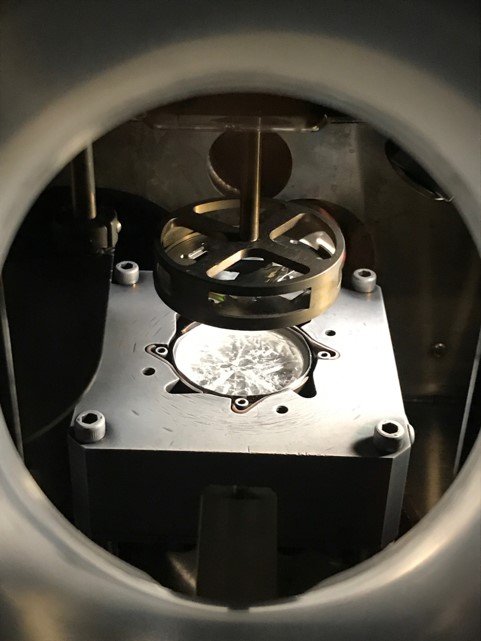

Adjusted from an innovation concocted in 1999 called MAPLE, the method includes solidifying an answer containing the atomic building hinders for the perovskite, and after that shooting the solidified piece with a laser in a vacuum chamber.

At the point when a laser vaporizes a little bit of the solidified focus about the measure of a dimple on a golf ball, the vapor ventures upward in a tuft that coats the base surface of any question hanging overhead, for example, a segment in a sun-based cell. When enough of the material develops, the procedure is ceased and the item is warmed to solidify the particles and set the thin film set up.

In Stiff-Roberts’ form of the innovation, the laser’s recurrence is particularly tuned to the atomic obligations of the solidified dissolvable. This makes the dissolvable assimilate the majority of the vitality, leaving the fragile organics unscathed as they go to the item surface.

Stiff-Roberts said, “The RIR-MAPLE technology is extremely gentle on the organic components of the material, much more so than other laser-based techniques. That also makes it much more efficient, requiring only a small fraction of the organic materials to reach the same final product.”

“While solution-based techniques can also be gentle on organics and can make some great hybrid photovoltaic materials, they can’t be used for more complex and poorly soluble organic molecules.”

“With this demonstration of the RIR-MAPLE technology, we hope to open a whole new world of materials to the solar cell industry. We also think these materials could be useful for other applications, such as light-emitting diodes, photodetectors, and X-ray detectors.”

The research team described their methods Dec. 22, 2017 in the journal ACS Energy Letters.